Frequently Asked Questions

After more than 45 years in business, and helping companies small and large the world over, we are frequently asked questions by our customers.

Here are just a few of the frequently asked questions, followed by the best answers we can provide. If you have a question for us, just get in touch; the answer may end up on this page!

Make This One Blank

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Why should I choose Universal Filling Machine Company?

Looking for a reliable, high-quality liquid filling machine? Since 1976, Universal Filling Machine Company has been designing and manufacturing filling and capping machines, delivering precision-engineered solutions to businesses worldwide.

Quality You Can Trust

We build every bottle filling machine in-house to meet the highest standards, ensuring exceptional performance and long-term reliability. Our food- and pharmaceutical-grade materials, including certifiable 316 stainless steel contact parts, guarantee product safety and durability. Before delivery, we rigorously test each machine using your actual products and containers to ensure it performs flawlessly from day one.

Built to Last

Our automatic filling machines are designed for minimal maintenance and maximum efficiency. Many of our customers still use their first filling machine from the 1990s, thanks to our industry-leading build quality. With over 70% of our customers returning, it’s clear that reliability and excellent customer service set us apart.

Dedicated Customer Support

We don’t just sell filling equipment—we build long-term partnerships. After installation, a senior director will personally follow up to ensure you’re completely satisfied with your automatic liquid filling machine and our service. Your honest feedback helps us improve and continue delivering top-tier solutions.

So, whether you need a small-scale bottling machine or a high-speed automatic filling system, Universal Filling Machine Company is ready to help. Get in touch today to discuss your project!

How Do I Buy A Filling Machine?

How to Buy a Liquid Filling Machine

Investing in the right liquid filling machine is an important decision, and at Universal Filling Machine Company, we make the process as smooth and straightforward as possible.

Whether you need a bottle filling machine, an automatic filling machine, or a semi-automatic solution, our expert team will guide you through every step to ensure you get the best system for your needs.

Step 1: Get in Touch

To begin, simply fill out the enquiry form on any product page, email us at salesuk@universalfilling.com, or call us on +44 (0)1233 643666.

Our experienced sales team will take the time to understand your requirements, ensuring we recommend the most suitable filling equipment for your application. Whether you’re filling small bottles, large containers, or viscous liquids, we’ll help you find the right solution.

Step 2: Expert Consultation & Testing

Once we understand your needs, we take things a step further to ensure your chosen filling machinery meets your exact specifications. We’ll ask you to send samples of your product and containers, allowing our engineers to conduct in-house tests.

By testing with your actual materials, we can accurately assess the performance, efficiency, and suitability of our filling and capping machines for your application.

After testing, we share the results with you, providing clear performance data so you can make a well-informed decision with confidence.

Step 3: Placing Your Order

When you’re ready to proceed, we’ll discuss payment terms and delivery schedules.

Since we manufacture most automatic liquid filling machines to order, this step ensures that your system is built to match your exact needs.

However, we also keep a small stock of our most popular bottling machines, which may help reduce lead times in some cases.

Need More Information?

For further details, explore our full range of semi-automatic and fully automatic liquid filling machines. If you have any questions, don’t hesitate to contact us today—our team is ready to help!

Contact us today, and let’s get started!

What is a volumetric filler?

A Volumetric Filler is a machine which dispenses a specific volume of liquid in to a container in a repeatable, accurate way.

Widely used in commerical packaging and similar industrial applications; bottles, jars, tins, pots, and similar containers can be filled with a variety of products such as drinks, lotions, sauces, chemicals, solvents, paints, cosmetics, pharmaceuticals, oils, detergents, bleaches, acids, alkalines and many more liquids.

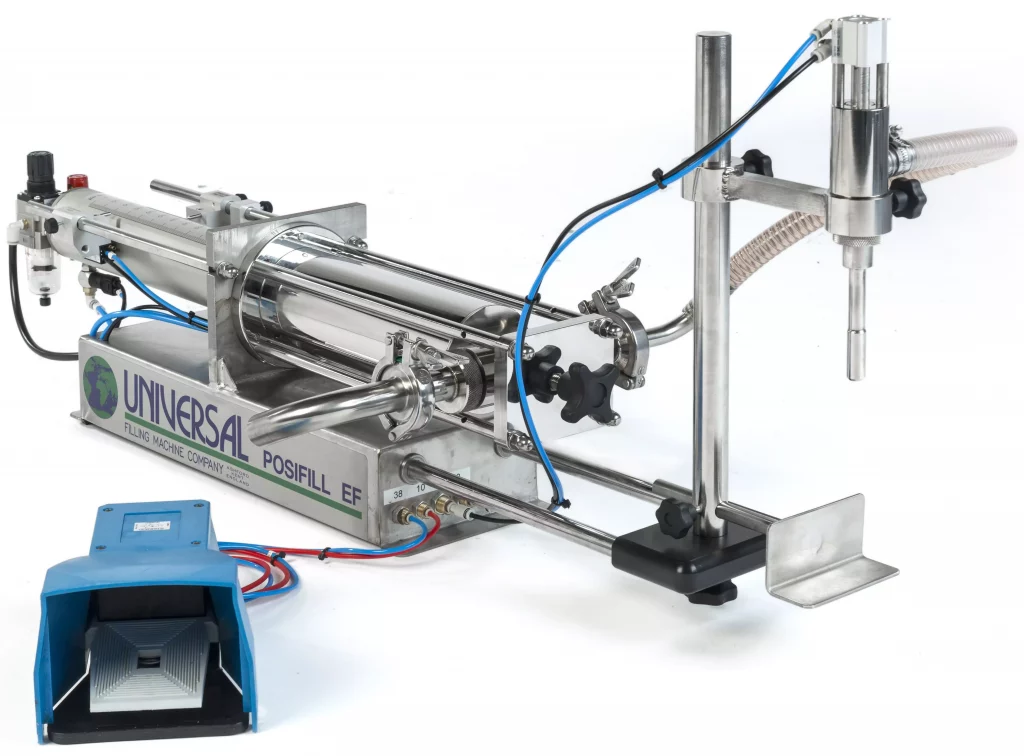

Volumetric fillers can range from hand-operated, manual machines through to highly automated production lines, and can fill volumes from 5ml to 5 litres in a single cycle. Multi-shot counters can also be used. These allow a number filling cycles to be completed in a single operation – a single press of the foot switch can be used to trigger 5×5 litre fills, giving a total of 25 litres in a single action.

Volumetric fillers can range from hand-operated, manual machines through to highly automated production lines, and can fill volumes from 5ml to 5 litres in a single cycle. Multi-shot counters can also be used. These allow a number filling cycles to be completed in a single operation – a single press of the foot switch can be used to trigger 5×5 litre fills, giving a total of 25 litres in a single action.

Most volumetric filling machines use a pneumatically-powered piston within a cylinder. The piston is forced forwards and backwards for each filling cycle.

During this motion, a valve controls the flow of liquid; allowing the cylinder to fill with liquid from the supply as the piston moves away from the valve, and allowing the liquid to exit the via the outled side as the piston moves forwards.

The distance the piston travels within the cylinder determines the volume of liquid it displaces. This distance can be set to give the desired fill volume. The speed of the piston’s movement can also be controlled fore and aft to ensure accurate filling volumes are achieved at acceptable speeds.

The distance the piston travels within the cylinder determines the volume of liquid it displaces. This distance can be set to give the desired fill volume. The speed of the piston’s movement can also be controlled fore and aft to ensure accurate filling volumes are achieved at acceptable speeds.

A filling nozzle is connected to the outlet side of the valve. This nozzle plays an important role in the filling process; it’s design, diameter and length should be specified to suit the liquid container and to prevent dripping and any other undesired characteristics.

The infeed side of the metering cylinder’s valve is connected to either hopper or supply tank via a feed pipe, replenishing the cylinder as it moves backwards after each fill.

Universal Filling Machine Company manufacture several machines which use this filling principle and offer additional features such a secondary filling speed as an option. This allows for the latter part of the filling cycle to be completed at a reduced speed to avoid liquids splashing as a result of filling too fast. The speed and starting point of the secondary fill can both be set and have no effect on the overall filling volume.

How do I choose the right liquid filling machine?

When choosing which filling machine is the right one for you, the best method is to focus on your requirements of the system and identify the idea specification. Some of the main things to consider are:

The viscosity.

Does the liquid in question flow freely, or is it a higher viscosity? In general terms, the higher a liquid’s viscosity, the fewer filling options there are available.

Free-flowing, low viscosity liquids can often be filled by either a volumetric system which uses a pneumatically powered piston to displace a predetermined amount of liquid, or by a vacuum filling system which uses a special filling nozzle arrangement to draw liquid into the bottle by suction.

The container.

The size, shape, and material a container is made from will influence the type of machine used to fill it. Most rigid plastic or glass bottle can be filled with thinner, free-flowing liquids via a vacuum-level filling machine, whilst jars, flexible bottles or pouches are likely to require a volumetric filling system. Large containers above 5-litres may require a volumetric system with a mobile ‘Wander Nozzle’ to allow the operator to fill the containers at ground level.

Fill accuracy.

The level of accuracy required can also influence the choice of liquid filling system. In situations where the finished product is visible within the bottle and displayed in a retail environment, a vacuum level filling system may be appropriate because it will fill bottles to the same height, regardless of any differences from one container to another. This is particularly useful when filling glass bottles as the glass thickness can vary substantially.

Where a consistent, dependable fill volume is required and the aesthetics of several bottles displayed side-by-side on a shelf is not important, a volumetric filling system will provide a greater level of accuracy (commonly +/-0.5%). Volumetric filling systems work with a wider range of viscosities and container types.

Many of our volumetric filling machines have the added benefit of a variable, user specified ‘secondary fill volume’ which reduces the filling speed towards the end of each cycle, preventing liquid from splashing out of the top in the final stage of filling.

Production scale.

The number of containers to be filled has a direct correlation with the level of automation the suitable filling system should have. Production scales of a between a few dozen and a few hundred can – in many cases – be achieved using either a manual or semi-automatic filling system, whereas regular production runs upwards of 1,000 are likely to require a greater level of automation through the filling process to achieve a high enough production rate. Semi-automatic and manual filling systems tend to be quicker to clean and changeover for a different filling application than fully automatic filling systems.

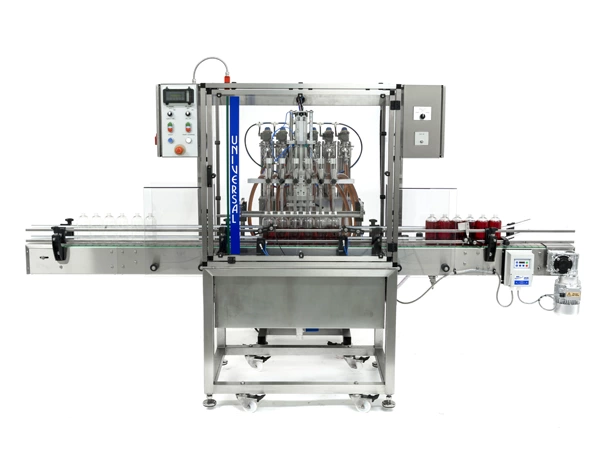

Production scales can be increased in several ways: conveyor systems to pass containers through the filling process automatically, multi-headed filling systems can fill up to 12 containers simultaneously, rotary infeed and outfeed tables can allow operators to place and remove numerous containers more rapidly. Additional systems can also be added such as capping and labelling to further increase production output.

Production environment.

Manual filling machines such as our Handifill range can – for the most part – be used almost anywhere provided there is a firm surface to secure the machine to. Semi- automatic and fully automatic filling equipment will require either a supply of compressed air, electricity or both. Our liquid filling systems can be specified for use in ATEX environments.

Other considerations.

Apart from the items listed above, there are a few other things to consider when choosing the right filling machine for your application. The type of liquid is a major factor. The contact parts within our filling machines are made from food- and pharmaceutical-grade 316 stainless steel.

Hoses, internal seals and valve assemblies are often specified to suit the type of liquid to be filled, whether it be Whisky or printer ink, paint or car wax; the materials used within the filling system need to be specified to suit to avoid contamination or premature seal degradation and failure. For example, piston seals which can withstand the rigours of dispensing acids may not be accredited for use within food or drinks production.

Another item influenced by the liquid type is the nozzles used. Nozzles are made to suit each application, container types and fill volume. Although often overlooked, the nozzle design can have a huge impact on the capability of a filling system to cleanly and efficiently fill containers time and again.

The characteristics of a liquid also play a part in the specification of a filling system and its nozzle design. Particularly ‘sticky’ liquids, such as syrup, may be similar viscosity to a hair gel, yet is likely to ‘cling’ to surfaces more readily than gel. Equally, printer ink can be the same viscosity as detergent but less likely to foam when dispensed. These characteristics will be addressed in the design of the nozzle in order to dispense cleanly and efficiently.

How do you fill multiple bottles at once?

The simplest methods of filling numerous bottles simultaneously is to use a multi-head filling machine.

Semi-automatic filling machines can often have 2 or even 4 filling heads and fully automatic filling machines can have as many as 12 filling heads.

Each filling head has its own nozzle and bottles are positioned beneath them for filling.

In some cases, multi-head vacuum level filling machines, such as the Easifill can be set up to fill ‘continuously’. Bottles can be positioned for filling in sequence 1 through to 4. Bottle 1 is likely to finish filling first and can be replaced first, then bottle 2, 3, and 4.

Fully-automatic filling machinery can fill up to 12 bottles at once, before releasing them to make way for the next 12 bottles. The level of automation available with such machines can make their productivity many times that of any semi-automatic filling system.

How much does a filling machine cost?

If you’re searching for filling machine prices, you may have noticed that manufacturers rarely list exact costs online.

That’s because the price of a liquid filling machine depends on various factors, including machine type, automation level, production capacity, and customisation options. At Universal Filling Machine Company, we manufacture high-quality bottle filling machines designed to grow with your business, ensuring you get the best value for your investment.

Factors That Affect Filling Machine Price

Type of Filling Machine

The cost of a filling machine depends largely on whether you need a semi-automatic or automatic filling machine.

Semi-automatic models are a cost-effective solution for smaller-scale production, while fully automatic liquid filling machines offer higher throughput, reduced labour costs, and greater efficiency — making them the best long-term investment for larger production lines.

Production Capacity

The speed and output of a bottling machine play a significant role in determining its price. Machines designed for high-speed production require advanced motors, precision components, and robust engineering, which can increase initial costs.

However, investing in a high-capacity automatic filling machine often leads to long-term savings by improving efficiency and reducing downtime.

Filling Method & Product Type

Different liquids require different filling equipment. A bottle filling machine designed for water or low-viscosity liquids differs from one built for thicker pastes, foamy products, or particulate-filled substances.

The choice between volumetric, gravity, piston, or vacuum-based filling affects cost, performance, and accuracy. Selecting the right filling machinery ensures efficiency and minimises waste.

Customisation & Compliance

Many businesses require custom-built solutions to meet their specific production needs. Whether integrating with existing bottling machines, using special materials, or ensuring regulatory compliance, these factors can influence pricing.

For example, industries handling hazardous products may require ATEX-certified filling machines, which involve additional safety features and engineering considerations.

How a High-Quality Filling Machine Saves Money Over Time

While a lower-cost filling machine might seem appealing, investing in a high-quality system provides long-term savings through improved efficiency, reliability, and accuracy.

Greater Accuracy = Less Waste

Precision-engineered filling machinery ensures that every bottle, container, or jar is filled consistently, reducing product loss and minimising waste. Over time, even small inaccuracies can result in significant financial losses.

Exceptional Reliability = Minimal Downtime

Downtime due to machine failures can be costly. Investing in a well-built filling machine with high-quality components reduces maintenance needs and keeps your production running smoothly. Many of our customers are still using their first Universal Filling Machine decades later, with only routine servicing required.

Versatility = Future-Proofing Your Investment

A high-quality bottle filling machine should adapt as your business grows. Our machines are designed to handle a wide range of liquids, container sizes, and production requirements, allowing you to expand your product range without needing to invest in new equipment.

Built for the Future: Upgradeable and Scalable Machines

At Universal Filling Machine Company, we understand that production demands change over time. That’s why we design our machines to be modular and upgradeable, allowing you to enhance performance as your business grows.

Future-Proofing Your Investment

Instead of replacing your filling equipment when demand increases, you can retrofit our machines with production-enhancing upgrades. Whether it’s adding more filling heads, adding a capping system, rotary infeed and outfeed tables, or integrating automation, we provide scalable solutions that grow with your needs.

Minimise Disruptions, Maximise Productivity

Unlike rigid, single-purpose machines, our adaptable designs mean you won’t have to halt production for a costly equipment overhaul. Our upgrade options allow for seamless integration without extensive downtime, ensuring your business remains competitive and efficient.

A Key Component of Our Ethos

Our commitment to sustainability, cost-effectiveness, and long-term customer satisfaction is at the heart of our approach. By designing filling machinery that evolves with your business, we help you avoid unnecessary capital expenditure while continuously improving your production capabilities.

The Value of Exceptional Customer Service & After-Sales Support

Beyond the machine itself, customer support plays a crucial role in ensuring long-term success.

Choosing a filling machine supplier that provides expert guidance, reliable support, and ongoing assistance can make all the difference in keeping your production running smoothly.

At Universal Filling Machine Company, we are committed to delivering outstanding customer service at every stage—from the initial consultation through to after-sales support.

Expert Consultation & Customised Solutions

We take the time to understand your exact needs before recommending a solution. Our team works closely with you to ensure that your automatic liquid filling machine or semi-automatic system is the perfect fit for your production process.

Comprehensive After-Sales Support

Once your machine is installed, we don’t just leave you to figure it out alone. We offer:

- Full operator training to ensure your team can use the machine effectively.

- Technical support and troubleshooting to minimise downtime.

- Ongoing maintenance services to keep your equipment running at peak performance.

Customer Satisfaction Guarantee

We believe in building long-term relationships with our customers. That’s why, after installation, one of our senior directors will personally follow up to ensure you’re completely satisfied with your filling equipment and the support you’ve received. Your feedback helps us continue to improve and provide the best service possible.

Finding the Right Filling Machine for Your Budget

Instead of focusing solely on upfront costs, it’s important to look at long-term efficiency, durability, and return on investment.

A high-quality liquid filling machine may have a higher initial cost, but the long-term benefits—such as lower maintenance expenses, reduced waste, and increased production capacity—make it a far more cost-effective solution.

At Universal Filling Machine Company, we are dedicated to helping you find the most cost-effective filling solution for your business. Whether you need a semi-automatic bottle filling machine for a small production line or a fully automatic liquid filling machine for high-speed manufacturing, we have the expertise and experience to provide the right system for you.

Contact us today to discuss your requirements and receive a personalised quote—our team is ready to help!

What is a liquid filling machine?

In basic terms, a liquid filling machine is a device which provides a level of mechanisation, repeatability, and productivity to the process of filling containers with liquids.

The level of mechanisation, repeatability and productivity is determined by several factors; such whether the machine is connected to a power source or hand-operated, the speed at which it can repeat a dispensing or filling cycle and the volume of liquid it is capable of dispensing in a single cycle.

Most liquid filling machines have a range of volumes they can be set to fill in a single cycle, however, vacuum level filling machines fill containers with liquid until a specified height within the container is reached, rather than volume.

This height is determined by the position of the filling nozzle within the container and, more specifically, the position of a scavenger tube within the nozzle design which draws surplus liquid away to be returned to the supply source.

How does a bottle capping machine work?

A capping machine is a mechanism for securing a cap onto a container, such as a bottle, jar or vial. There are numerous types of caps and numerous securing methods. Each requiring a different type of capping machine for the job.

Screw Caps

Probably the most common type of cap for plastic bottles and jars, screw caps are simply pre-threaded caps made from either plastic or metal. They are placed on to the container and turned clockwise to tighten them. A specified torque is often set, at which tightening stops and the capping mechanism releases the completed container.

Crimp Caps

Widely used in pharmaceuticals, cosmetics and with spray pump applications, crimp caps are part-formed caps which are placed on to the container and a crimping tool is used to complete the caps forming, compressing its sides to follow the contours of the container’s neck and securing the cap firmly.

ROPP Caps

ROPP stands for Roll On Pilfer Proof, and refers to a cap type which is not dissimilar to a crimp cap in as much as it is part-formed before placing and completed during the final capping process. ROPP caps are widely used for drinks bottling and similar consumable products as once opened, the perforated lower rim of the cap is broken, making it evident that the container has been opened.

ROPP Caps are secured to the container by a rotating capping head which comprises a number of forming rollers. After several revolutions, these forming rollers form the aluminium blank cap to the contours of the bottle’s neck; which has a screw thread and a lower lip.

The forming process imparts the bottle’s screw thread on to the cap and rolls the bottom of the cap under the lip, making it impossible to open the bottle without breaking the tamper-evident perforations. ROPP caps are commonly used for wines, spirits, soft drinks, sauces and similar products.

Universal produce and supply a range of machines to cover all of the these cap types, from manually operated to fully automatic.

Explore our range of capping machines, or see videos of our capping machines in use.

Make This One Blank

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

What is the metal cap on a bottle called?

Widely referred to as a ‘screw cap’, the metal caps often used on wines and spirits which resembles a cork foil is known – in the industry at least – as an ROPP cap.

ROPP is an acronym of Roll On Pilfer Proof and refers to the cap fitting process along with the fact that the cap’s perforations and collar arrangement provide an anti-tamper feature; making it evident of the bottle’s cap has been removed or interfered with in any way.

Special equipment is required to fit ROPP caps to bottles, such as our ROPP Capper for small scale production, or the Posicap ROPP for higher production volumes.

Both systems apply the cap in a similar way. A ‘blank’ cap is positioned on top of the bottle and a capping head compresses the blank via rollers to mimic the shape of the bottle’s neck; including it’s screw thread. The bottle’s neck acts as a die for the cap to be formed around. The cap’s perforations are positioned below the between the thread and the bottleneck’s retaining ridge, creating the tamper-evident seal.

How does a bottling machine work?

Two distinct bottling technologies are available for semi-automatic and fully automatic bottle filling machines: volumetric and vacuum-level filling.

Manually operated bottle filling machines tend only to fill volumetrically whereas semi automatic and fully automatic bottle filling machines can be either volumetric or vacuum level fillers.

Volumetric bottling machines

Manual bottle filling machines use a piston within a cylinder to force liquid into the container.

These normally have a pneumatically powered pump mechanism, set to fill containers with the required volume of liquid, fed from either a floor-standing container or a machine-mounted hopper.

Containers are positioned below the filling nozzles and a foot pedal switch to start the filling process.

Volumes between 5ml and 25-litres can be handled by volumetric bottling machines and up to 150 containers per minute can be filled, depending on the fill volume, liquid viscosity and level of machine automation.

Vacuum level filling machines

Vacuum bottle filling machines use the rim at the top of the container to form an airtight seal around the filling nozzle.

This airtight seal creates a vacuum within the bottle which draws free-flowing liquids from a supply tank into the bottle, via specially designed nozzles. These nozzles have a small hole on the side which is connected to a small internal tube.

The height of this hole in relation to the top of the container during filling determines the level of liquid dispensed. The small hole in the nozzle scavenges excess liquid from the filling process and collects it in a receiver for reuse.

Vacuum level bottling machines fill containers to the same height each time, rather than dispensing the same volume. This is particularly useful for glass bottles which will be side-by-side on display shelves in shops. Glass bottles vary in capacity quite a lot, yet vacuum-level filling ensures the level each bottle is filled to is the same, giving a consistent appearance from one bottle to the next. Vacuum level bottling requires rigid containers which won’t collapse under a vacuum.

Vacuum-level machines have virtually no moving parts, making them incredibly reliable, and can fill up to 120 bottles per minute depending on the container type, number of filling heads and level of automation.

Bottles are simply positioned with their top in contact with a sealing ring around the nozzle. The container will start to fill as soon as an airtight seal is made and stop when the pre-determined fill height is reached.

Can a single filling machine handle different container sizes and fill volumes?

Yes. in almost all cases, liquid filling machines can handle a range of different container sizes and fill volumes.

The broadness of this range will vary from one type to another, as will the simplicity of changing from one container to another.

Some of our semi-automatic filling machines may require very little adjustment in some instances whereas some fully-automated filling lines may require different bottle handling components in order to transit the containers through the filling process.

The fill volume setting on volumetric filling machines takes just moments to set and fine tune. Many semi-automatic filling machines will then only require adjustment to the bottle rest and filling speed.

Of course, the more complex the filling machinery, the more variables there are which can be adjusted or changed, such as secondary filling speeds, nozzle position and – where applicable – dive height as well as nozzle types and sizes.

Any other functions integrated with the filling system such as capping and labelling that also require changing for a different container shape, size or volume should also be considered and will add to the time required to changeover.

Can Universal’s filling machines fill carbonated drinks?

Carbonated liquids have substantially different characteristics to still or non-carbonated liquids. They react to changes in pressure and agitation far more than liquids that are not carbonated.

The process of volumetric filling forces liquid into a container and the process of Vacuum Level filling draws liquid into a container by vacuum. Both processes will have an adverse effect on a carbonated liquid, causing it to fizz and overflow.

Most industrial-scale filling systems for carbonated drinks effectively produce a filling environment which is at a higher-than-atmospheric level of air pressure throughout the entire filling and capping cycle. The supply tank, filling system, and bottle are all pressurised with CO2 to an extent which forces some of the CO2 gas to be dissolved within the liquid while preventing it from fizzing and overflowing.

In such an environment, carbonated drinks behave much more like non-carbonated liquids and can be filled by gravity or volumetric filling.

Unfortunately, Universal Filling Machine Company don’t currently offer a system which maintains constant, balanced pressure throughout the filling cycle.

What is a bottle filling system?

A bottle filling system is a device for filling bottles, jars and similar containers with liquid in a repeatable and productive way.

There are a variety of bottle filling systems available; each one designed and manufactured with a particular production scale, filling method, fill volume, liquid type and viscosity in mind.

Bottle filling machines can be used for any quantity of production, from a handfull of containers up to full-scale production of thousands – or tens of thousands – of bottles.

Bottle filling systems will typically draw liquid from a large container such as an IBC tank, a hopper or similar, and dispense a predetermined quantity of liquid into bottles, jars or other containers via a nozzle.

Smaller scale bottle filling machines are often either manually operated (via a hand operated lever), or semi-automatic; powered by compressed air, electricity, or a combination of the two.

Bottle filling machines are used across a wide range of industries, from pharmaceuticals and cosmetics to solvents and paints, with everything included between.

Looking for more information? Take a look at our range of Semi-Automatic And Fully-Automatic Liquid Filling Machines.

How do I choose a filling machine?

There are a few things to consider in order to determine which type of filling machine will suit you best.

Firstly, what type of container do you want to fill?

If the containers are flexible, then a vacuum-level filling machine may not be suitable. Vacuum level bottle filling machines rely on the container’s rigidity and ability to withstand a vacuum whilst they are being filled. Bottles made from thin plastic tend to collapse during this process, so a volumetric filling system which simply pours liquid into the container is likely to be the better option.

What size of container do you want to fill?

Obviously, larger containers can take longer to fill than smaller ones, regardless of the filling method. Volumetric filling machines have a maximum volume of liquid they can dispense in a single cycle. Multiple cycles can be used to fill larger containers, alternatively, a vacuum level filling system may suit your needs better because they keep filling until the filling nozzle’s overflow hole is reached.

How many containers do you want to fill?

Production runs of a up to a thousand can potentially be achieved with manual filling machines in just a few hours, but if such productivity is required regularly, a greater level of automation might be adviseable to speed up the process and reduce labour costs.

How viscose is the liquid?

Volumetric filling machines can handle thicker liquids than vacuum-level filling machines. Volumetric liquid filling machines can also be adapted to accommodate liquids which contain particles.

Other factors to consider

Aside from the productivity of the filling system, other factors to consider are types of seals used throughout the machine.

Some liquids will rapidly degrade the wrong type of seals, and other seal types are not approved for food/drinks applications. It’s essential to take advice from an expert to find the correct configuration for your needs.

Additionally, it’s worth considering your chosen system’s ability to provide reliable, ongoing service with full support from the manufacturer. Are your filling requirements likely to cause heavy wear and tear on a lesser filling machine and will the manufacturer provide dependable service and maintenance and ongoing support when you need it?

Looking for more information? Take a look at our range of Semi-Automatic And Fully-Automatic Liquid Filling Machines.

How do filling machines work?

Two distinct filling technologies are available for semi-automatic and fully automatic filling machines: volumetric and vacuum-level filling. Manually operated filling machines tend only to fill volumetrically.

Volumetric filling machines

Manual liquid filling machines use a piston within a cylinder to force liquid into the container.

These normally have a pneumatically powered pump mechanism, set to fill containers with the required volume of liquid, fed from either a floor-standing container or a machine-mounted hopper.

Containers are positioned below the filling nozzles and a foot pedal switch to start the filling process.

Volumes between 5ml and 25-litres can be handled by volumetric filling machines and up to 150 containers per minute can be filled, depending on the fill volume, liquid viscosity and level of machine automation.

Vacuum level filling machines

Vacuum level semi-automatic filling machines use the rim at the top of the container to form an airtight seal around the filling nozzle.

This airtight seal creates a vacuum within the bottle which draws free-flowing liquids from a supply tank into the bottle, via specially designed nozzles. These nozzles have a small hole on the side which is connected to a small internal tube.

The height of this hole in relation to the top of the container during filling determines the level of liquid dispensed. The small hole in the nozzle scavenges excess liquid from the filling process and collects it in a receiver for reuse.

Vacuum level filling machines fill containers to the same height each time, rather than dispensing the same volume. This is particularly useful for glass bottles which will be side-by-side on display shelves in shops. Glass bottles vary in capacity quite a lot, yet vacuum-level filling ensures the level each bottle is filled to is the same, giving a consistent appearance from one bottle to the next. Vacuum level filling requires rigid containers which won’t collapse under a vacuum.

Vacuum-level machines have virtually no moving parts, making them incredibly reliable, and can fill up to 120 bottles per minute depending on the container type, number of filling heads and level of automation.

Bottles are simply positioned with their top in contact with a sealing ring around the nozzle. The container will start to fill as soon as an airtight seal is made and stop when the pre-determined fill height is reached.

Looking for more information? Take a look at our range of Semi-Automatic And Fully-Automatic Liquid Filling Machines.

How many types of filling machine are there?

Filling machines can be broken down in to 3 main categories: manual, semi-automatic and fully automatic. There are also two main filling technologies used – vacuum level filling and volumetric filling.

Manual Liquid Filling Machines

Manual liquid filling machines use a piston within a cylinder to force liquid into the container.

Known as volumetric filling, this technology dispenses the same volume every time.

The volume of liquid dispensed is pre-set by the operator for repeatability and can be changed within the available output volume range of the machine (between 100-500ml, for example). These machines require no power supply, are compact, and can often be bench mounted.

The operator positions the container in to the filling machine, pulls the lever until the end-stop is reached which forces the liquid out of the nozzle, into the container. In almost every case, manually operated liquid filling machines fill one container at a time.

Manual filling machines can be configured to work with a variety of liquids and a wide range of viscosities.

Depending on the liquid’s viscosity and volume dispensed per cycle, filling speeds of 15 containers per minute are likely.

Semi-automatic liquid filling machines

Semi-automatic liquid filling machines fulfil the same purpose as manual machines but have a source of power which allows for higher productivity.

Semi-automatic filling machines can have up to four filling heads, meaning 4 containers can be filled simultaneously which greatly increases productivity.

Many semi-automatic filling machines use the same principle as manual filling machines to dispense liquid into the container, but rather than pulling a lever, the operator either presses a foot pedal switch, or simply positions the containers in place and they fill by themselves; depending on the filling technology used.

Semi-automatic filling machines can be either freestanding, mobile units or bench-mounted and can draw liquid from either a hopper or from a separate vessel via feed tubes.

Fully automatic liquid filling machines

Fully automatic filling machines can be either volumetric filling or vacuum level filling and have the added production benefit of a bottle handling system to manoeuvre containers through the filling stage and seamlessly on to any further processes such as cap placement and label application.

Additional processes can also include nitrogen purging to remove oxygen from the top of filled bottles and individual serial number printing.

Commonly, containers will be placed on to a rotating feed table or similar mechanism which feeds containers into the filling machine as required. Caps can also be fed into the system via a rotating hopper which can correctly orientate them and position them in a chute for placement.

Depending upon a variety of factors, fully automatic filling machines will either fill each container in turn, or in batches of up to 12 containers at a time before releasing them to make way for the next 12 containers.

Fully automatic filling machines can be highly productive, filling up to 150 bottles per minute with anything from 5ml to 5.5 litres.

Make This One Blank

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

What is a filling machine?

A filling machine, or liquid filling machine, is a device for filling containers, such as bottles or jars, with liquid in a repeatable and productive way.

There are a variety of filling machine types available; each one designed and manufactured with a particular production scale, filling method, fill volume, liquid type and viscosity in mind.

Filling machines can be used for any quantity of production, from just a few jars of liquid up to full-scale production of thousands – or tens of thousands – of bottles.

Liquid filling machines will typically draw liquid from a large container such as an IBC tank, a hopper or similar, and dispense a predetermined quantity of liquid into bottles, jars or other containers via a nozzle.

Smaller scale liquid filling machines are often either manually operated (via a hand operated lever), or semi-automatic; powered by compressed air, electricity, or a combination of the two.

Bottle filling machines are used across a wide range of industries, from pharmaceuticals and cosmetics to solvents and paints, with everything included between.

How Does An Automatic Liquid Filling Machine Work?

Automatic liquid filling machines fill bottles and similar containers automatically via a conveyor system; effectively removing the requirement for an operator to position individual containers for filling and removing them upon completion.

Linear automatic liquid filling machines can handle up to 12 containers or bottles per cycle (depending on their size); resulting in a far higher output than a semi-automatic liquid filling machine with minimal operator input.

Universal’s automatic liquid filling machines comprise two main elements; a Filling Chassis and a Bottle Handling Module. In very simple terms, the Filling Chassis provides the right quantity of liquid while the Bottle Handling Module provides the right quantity of bottles.

The Filling Chassis and Bottle Handling Module are pneumatically connected to each other in order to work in perfect synchronisation, in conjunction with a Bottle Gating System.

Automatic Liquid Filling Machines offer far higher production speeds in comparison to Semi-Automatic liquid Filling Machines and can be directly connected to other machines, such as capping and labelling machines to form a complete and fully automatic production line.

Volumetric Filling Chassis

Sitting behind the Bottle Filling module, a Volumetric Filling Chassis comprises a metering cylinder and piston assembly which draws liquid from the bulk supply as the piston retracts. A valve arrangement controls the flow of liquid, ensuring it flows in the correct direction. Each filling head and nozzle requires it’s own dedicated piston, cylinder and valve assembly. As such, a 6-head filling machine will have 6 cylinders, 6 pistons and 6 valves. When a filling cycle starts, the Metering Piston pushes liquid out of the Metering Cylinder via the Metering Valve and towards the filling head and nozzle assembly.

Vacuum Filling Chassis

Alternatively, a Vacuum Filling Chassis use the creation of a vacuum within in the bottles to draw liquid from the supply. The design of the filling nozzles creates an airtight seal around the top of the bottle and ensures the correct filling height is achieved.

When a filling cycle starts, the Metering Piston pushes liquid out of the Metering Cylinder via the Metering Valve and towards the filling head and nozzle assembly.

Bottle Handling Module

The Bottle Handling Module consists of a conveyor system which takes empty containers or bottles, positions them below the filling heads, lowers the filling heads during filling and raises them afterwards before releasing the filled containers to make way for the next batch.

A series of sensors within the Bottle Handling Module ensure the correct number of containers pass through the pneumatic Gating System before lowering the filling heads and starting to fill.

Gating System

The Gating System – a mechanism of pneumatically powered paddles – controls the flow of bottles through the automatic liquid filling machine; literally blocking the bottles’ path at a set point, preventing them going any further until the appropriate moment.

An entry gate allows bottles to enter the machine upon completion and release of the previous batch whilst the exit gate releases the filled bottles, allowing them to exit the machine.

What Is A Filling Machine Used For?

A Filling Machine is a device for accurately and repeatably dispensing liquids to a predetermined volume or level within a container.

Often pneumatically powered, they provide a provide a productive method of filling containers, bottles, jars and similar vessels with a variety of liquids as part of the commercial packaging process.

A wide variety of liquids can be filled with Universal’s range of liquid filling machines, from free-flowing liquids such as water and drinks, through to thicker sauces, gels, lotions and syrups.

Universal’s liquid filling machines are built using he highest quality food and pharmaceutical grade 316 stainless steel contact parts, so are ideal for many consumable products and are built to withstand the rigours of time and extensive use with minimal maintenance.

Specialised machines with glass and PVC contact parts are also available for filling substances such as acids, alkalis and bleaches which can corrode and degrade stainless steel.

Filling machines are widely used in industries which depend upon containers being filled with liquids, such as the cosmetics industry, food and drinks, cleaning products, pharmaceuticals, petrochemicals, paints and coatings, automotive products and home and gardening products.

Filling machines draw liquid from a bulk supply vessel via a feed pipe, or from a hopper and allow the operator to determine and dispense specific quantities of the liquid into containers as required.

Once filled, these containers can pass to the next stage of the process; often cap placement and tightening.

How Does An Automatic Bottle Filling Machine Work?

Automatic bottle filling machines fill bottles and similar containers automatically via a conveyor system; effectively removing the requirement for an operator to position individual containers for filling and removing them upon completion.

Linear automatic bottle filling machines can handle up to 12 containers or bottles per cycle (depending on their size); resulting in a far higher output than a semi-automatic liquid filling machine with minimal operator input.

Universal’s automatic bottle filling machines comprise two main elements: a Filling Chassis and a Bottle Handling Module. In very simple terms, the Filling Chassis provides the right quantity of liquid while the Bottle Handling Module provides the right quantity of bottles.

The Filling Chassis and Bottle Handling Module are pneumatically connected to each other in order to work in perfect synchronisation, in conjunction with a Bottle Gating System.

Automatic Bottle Filling Machines offer far higher production speeds in comparison to Semi-Automatic liquid Filling Machines and can be directly connected to other machines, such as capping and labelling machines to form a complete and fully automatic production line.

Volumetric Filling Chassis

Sitting behind the Bottle Filling module, a Volumetric Filling Chassis comprises a metering cylinder and piston assembly which draws liquid from the bulk supply as the piston retracts. A valve arrangement controls the flow of liquid, ensuring it flows in the correct direction. Each filling head and nozzle requires it’s own dedicated piston, cylinder and valve assembly. As such, a 6-head filling machine will have 6 cylinders, 6 pistons and 6 valves. When a filling cycle starts, the Metering Piston pushes liquid out of the Metering Cylinder via the Metering Valve and towards the filling head and nozzle assembly.

Vacuum Filling Chassis

Alternatively, a Vacuum Filling Chassis use the creation of a vacuum within in the bottles to draw liquid from the supply. The design of the filling nozzles creates an airtight seal around the top of the bottle and ensures the correct filling height is achieved.

When a filling cycle starts, the Metering Piston pushes liquid out of the Metering Cylinder via the Metering Valve and towards the filling head and nozzle assembly.

Bottle Handling Module

The Bottle Handling Module consists of a conveyor system which takes empty containers or bottles, positions them below the filling heads, lowers the filling heads during filling and raises them afterwards before releasing the filled containers to make way for the next batch.

A series of sensors within the Bottle Handling Module ensure the correct number of containers pass through the pneumatic Gating System before lowering the filling heads and starting to fill.

Gating System

The Gating System – a mechanism of pneumatically powered paddles – controls the flow of bottles through the automatic liquid filling machine; literally blocking the bottles’ path at a set point, preventing them going any further until the appropriate moment.

An entry gate allows bottles to enter the machine upon completion and release of the previous batch whilst the exit gate releases the filled bottles, allowing them to exit the machine.

How To Operate Filling Machine

Operating a filling machine depends on the type and scale of machine in question, although similar principles apply to all.

A suitable supply of compressed air is required along with a bulk supply of liquid for the machine to draw from. The appropriate quantity of liquid and the speed of fill needs to be determined and set. The bottle handling mechanism or rest assembly also needs to be set-up and the system needs to be primed to replace the air in the system with the liquid before production can commence. This is a relatively quick process for Universal’s machines and is covered in detail in the User Guide for each machine.

Universal’s range of semi-automatic volumetric liquid filling machines are operated by positioning a bottle on the Bottle Rest and pressing a foot-operated start switch. Once the set filling volume is reached, filing stops and the process can be repeated with a fresh container. Take a look at our range of semi-automatic liquid filling machines.

Universal’s range of fully automatic liquid filling machines use a conveyor mechanism to pass bottles or containers through the entire filling process, taking empty bottles at one end and delivering filled bottles at the other end of its conveyor system. Explore our range of fully automatic liquid filling machines.

What Is The Function Of A Filling Machine?

A Filling Machine is a device for accurately and repeatably dispensing liquids to a predetermined volume or level within a container.

Often pneumatically powered, they provide a productive method of filling containers, bottles, jars and similar vessels with a variety of liquids as part of the commercial packaging process.

A wide variety of liquids can be filled with Universal’s range of liquid filling machines, from free-flowing liquids such as water and drinks, through to thicker sauces, gels, lotions and syrups.

Universal’s liquid filling machines are built using he highest quality food and pharmaceutical grade 316 stainless steel contact parts, so are ideal for many consumable products and are built to withstand the rigours of time and extensive use with minimal maintenance.

Specialised machines with glass and PVC contact parts are also available for filling substances such as acids, alkalis and bleaches which can corrode and degrade stainless steel.

Filling machines are widely used in industries which depend upon containers being filled with liquids, such as the cosmetics industry, food and drinks, cleaning products, pharmaceuticals, petrochemicals, paints and coatings, automotive products and home and gardening products.

Filling machines draw liquid from a bulk supply vessel via a feed pipe, or from a hopper and allow the operator to determine and dispense specific quantities of the liquid into containers as required.

Once filled, these containers can pass to the next stage of the process; often cap placement and tightening.

What Are Liquid Filling Machine Uses?

A Liquid Filling Machine is a device for accurately and repeatably filling liquids to a pre-set volume or level within a bottle, jar or similar container.

Often pneumatically powered, they provide a productive method of filling containers, bottles, jars and similar vessels with a variety of liquids as part of the commercial packaging process.

A wide variety of liquids can be filled with Universal’s range of liquid filling machines, from free-flowing liquids such as water and drinks, through to thicker sauces, gels, lotions and syrups.

Universal’s liquid filling machines are built using he highest quality food and pharmaceutical grade 316 stainless steel contact parts, so are ideal for many consumable products and are built to withstand the rigours of time and extensive use with minimal maintenance.

Specialised machines with glass and PVC contact parts are also available for filling substances such as acids, alkalis and bleaches which can corrode and degrade stainless steel.

Filling machines are widely used in industries which depend upon containers being filled with liquids, such as the cosmetics industry, food and drinks, cleaning products, pharmaceuticals, petrochemicals, paints and coatings, automotive products and home and gardening products.

Filling machines draw liquid from a bulk supply vessel via a feed pipe, or from a hopper and allow the operator to determine and dispense specific quantities of the liquid into containers as required.

Once filled, these containers can pass to the next stage of the process; often cap placement and tightening.

Check out our latest customer satisfaction survey

Universal Filling Machines has always had a strong customer service ethos, which we feel sets us apart from many of our competitors.