Bottle Filling Machines for Liquids – Designed & Built in the UK

Precision Bottle Filling Machines for Efficient Production

Universal Filling Machine Company designs and builds bottle filling machines in the UK for liquids of all types.

Our machines are configured to suit your product, bottle size, and production requirements, helping manufacturers and contract packers achieve precise, reliable filling every time.

This page will guide you through the types of machines available and help you choose the right solution for your operation.

Choosing the Right Bottle Filling Machine

Selecting the right bottle filling machine depends on your bottle type, production speed, and liquid characteristics.

Use semi-automatic machines for flexibility and small-medium production, or fully automatic machines for high-speed, high-volume operations. Consider bottle material (plastic, glass), neck size, viscosity, and any particulates in the liquid — this page will guide you to the ideal solution.

Types of Bottle Filling Machines

Universal Filling Machine Company designs and builds bottle filling machines in the UK for liquids of all types.

Our machines are configured to suit your product, bottle size, and production requirements, helping manufacturers and contract packers achieve precise, reliable filling every time. This page will guide you through the types of machines available and help you choose the right solution for your operation.

Universal’s Bottle Filling Machines fall in to one of two categories; Semi-Automatic or Fully Automatic, and two distinct filling technologies are used; Vacuum Level Filling or Volumetric Filling, depending on the containers and liquids being filled.

Level of Automation

Filling Principle/Technology

Semi-Automatic Bottle Filling Machines

Bottles are hand-placed and each filling cycle is started by the operator

Ideal for low to medium production runs

Flexible for various bottle sizes and liquids

Great for startups, small and medium enterprises

Portable, compact and quick to set-up

Fill volumes can range from 10ml to 25 litres

Machines can be upgraded to handle increasing future demand

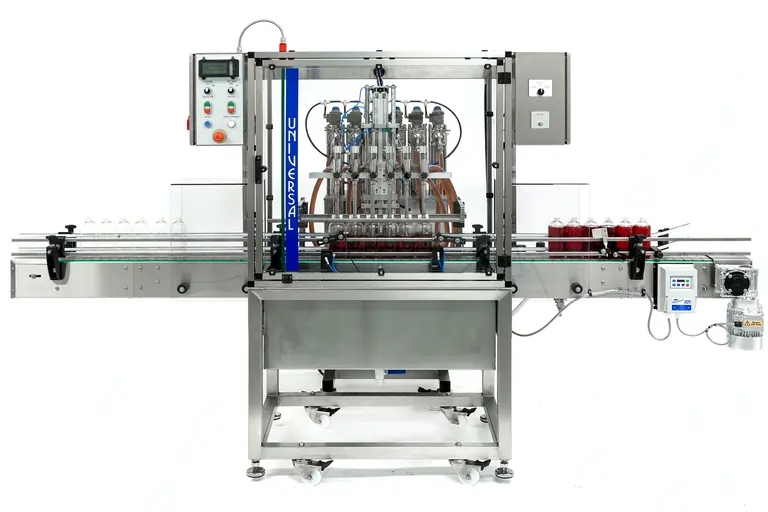

Fully Automatic Bottle Filling Machines

Bottles are supplied via conveyor system and each filling cycle is started automatically

High-speed output for larger operations

Fully configurable for liquids of different viscosities

Suitable for medium to high-volume manufacturers

Easily adjusted to fill a variety of liquids containers and fill volumes.

Can seamlessly combine with other packaging operations, such as capping or labelling

Vacuum Level Bottle Filling Machines

Bottles are filled by creating a vacuum within the bottle, causing liquid to be drawn in

Precise, consistent level fills, ideal for products on retail display

Requires rigid containers such as glass bottles to work

Works well with low-viscosity liquids such as perfumes and drinks

Good for sensitive liquids and hygienic production

Piston Fillers/Volumetric Bottle Filling Machines

Bottles are filled by the motion of a piston within a cylinder to displace liquid

Excellent for viscous or thick liquids

Works with particulate-containing liquids

Variants available for acids, bleaches and similar products

Ideal for flexible containers such as plastic bottles

Ranges from tabletop semi-automatic to large freestanding automatic machines

Fully Automatic Bottle Filling Machines

Our Automatic Bottle Filling Machines are built for high-speed, high-volume production. With electro/pneumatic PLC controls, these machines handle liquids of all types — including viscous liquids and those with particulates — and accommodate containers from 5 ml to 5 L.

Designed for easy setup, quick changeovers, and user-friendly operation, they minimise downtime while maximising throughput for bottles of all shapes and sizes.

Semi-Automatic Bottle Filling Machines for Small to Medium Production

For small to medium production, our semi-automatic bottle filling machines provide precision, flexibility, and cost-effectiveness.

Perfect for businesses transitioning from manual to automated processes, they handle a wide array of liquid viscosities and bottle types. Manual control allows fine-tuning for specific bottles, while maintaining consistent fill levels and reducing waste.

Semi-Automatic Bottle Filling Machines for Small to Medium Production

For small to medium production, our semi-automatic bottle filling machines provide precision, flexibility, and cost-effectiveness.

Perfect for businesses transitioning from manual to automated processes, they handle a wide array of liquid viscosities and bottle types. Manual control allows fine-tuning for specific bottles, while maintaining consistent fill levels and reducing waste.

Why Choose Universal Bottle Filling Machines?

Versatility

Capable of handling a broad spectrum of liquid types and viscosities

Precision

Ensures accurate and consistent fill levels, reducing waste.

Scalability

Suitable for both small-scale operations and large production lines.

User-Friendly

Designed for straightforward setup and operation, minimising downtime.

Reliability

Built with high-quality materials to ensure long-lasting performance.

Reliability

Built with high-quality materials to ensure long-lasting performance.

Bottle Types Our Machines Can Fill

Small glass bottles for perfumes and tinctures

Plastic and PET bottles for lotions, shampoos, and cleaning products

Trigger spray bottles

Large 5‑litre jerry cans and drums

Industries Using Our Bottle Filling Machines

Our bottle filling machines are utilized across multiple industries, including:

Compare Automatic Liquid Filling Machines

| Model | Fill Volume Range | Maximum Speed | Filling Heads | Valve Type | Bottle Types | Format |

|---|---|---|---|---|---|---|

| Posimatic EV1000 | 5ml – 1,300ml | Up to 7,200 bottles/hour | 2, 4, 6, 8 or 12 | Rotary Valve or Ball & Spring | glass, plastic, metal bottle, jars, tins, tubs, etc. | Inline Automatic with Conveyor |

| Posimatic EV2500 | 100ml – 2,500ml | Up to 3,600 bottles/hour | 2, 4, 6 or 8 | Rotary Valve or Ball & Spring | glass, plastic, metal bottle, jars, tins, tubs, jerrycans etc. | Inline Automatic with Conveyor |

| Posimatic EV5000 | 250ml – 5,000ml | Up to 1,800 bottles/hour | 2, 4 or 6 | Rotary Valve or Ball & Spring | Jerrycans, tubs, bottles, tins, etc. | Inline Automatic with Conveyor |

| Posimatic EVL | 5ml – 5,000ml (model dependent) | Up to 3,600 bottles/hour | 1, 2, 4, 6 or 8 | Rotary Valve or Ball & Spring | glass, plastic, metal bottle, jars, tins, tubs, jerrycans etc. | Inline Automatic with Conveyor |

| Posivac | 2ml – 1,500ml | Up to 4,800 bottles/hour | 2 to 12 | N/A (vacuum filling) | Glass & rigid plastic bottles & containers | Inline Automatic with Conveyor |

| Posimatic Voluvac | 5ml – 5,000ml (typical) | Up to 17,200 bottles/hour | 2 to 12 | Rotary Valve & Vacuum Filling | Bottles, jars, jerrycans, tubs, pails | Inline Automatic with Conveyor |

| *Speeds are approximate and depend on fill volume, liquid characteristics, and operator efficiency. | ||||||

Compare Semi-Automatic Liquid Filling Machines

| Model | Fill Volume Range | Maximum Speed | Filling Heads | Valve Type | Container Types | Format |

|---|---|---|---|---|---|---|

| Posifill EF | 5ml – 1,300ml | Up to 1,800 containers/hour | 1 | Rotary Valve or Ball & Spring | Bottles, jars | Benchtop |

| Posifill EF2500 | 200ml – 2,500ml | Up to 1,800 containers/hour | 1 | Rotary Valve or Ball & Spring | Bottles, jars | Benchtop |

| Posifill DP | 5ml – 1,300ml | Up to 1,800 containers/hour | 1 | Rotary Valve | Bottles, tubs, trays | Benchtop |

| Vacufill | 10ml – 500ml (typical) | Up to 2,400 containers/hour | 1 or 2 | N/A (vacuum filling) | Glass & rigid plastic bottles, jars | Benchtop |

| Easifill | 10ml – 750ml (typical) | Up to 2,400 containers/hour | 1, 2, 4 or 6 | N/A (vacuum filling) | Glass & rigid plastic bottles, jars | Free-standing |

| Posifill V-Twin/Four | 5ml – 1,300ml | Up to 2,400 containers/hour | 2 or 4 | Rotary Valve or Ball & Spring | Bottles, jars | Free-standing |

| P5000 | 250ml – 5,000ml+ | Up to 900 containers/hour | 1 or 2 | Rotary Valve | Jerrycans, tubs, bottles | Free-standing |

| PB5000 | 500ml – 5,000ml+ | Up to 1,200 containers/hour | 1 or 2 | Rotary Valve | Bottles, cans, tubs, jerrycans | Free-standing |

| *Speeds are approximate and depend on fill volume, liquid characteristics, and operator efficiency. | ||||||

Frequently Asked Questions

What bottle sizes can your machines handle?

From 5 ml vials to 25 L drums, including plastic, glass, jars, and tall-neck containers

Can I fill multiple bottle sizes on the same machine?

Yes, with quick changeovers and adjustable heads

How fast can the machines fill bottles?

Speeds vary; see our tables for throughput per hour

Can viscous liquids or liquids with particulates be filled?

Yes, our machines handle a wide range of viscosities and particulates

Do your machines integrate with capping and labelling?

What industries use these machines?

Why Choose Universal Filling Machine Company?

50+ Years’ Experience as an Industry Leader

Built Using the Highest Quality Components and Materials

Machines Can Be Specified To Suit Almost Any Liquid

Outstanding Customer Service

Customers in Over 80 Countries Around the World

Designed and Manufactured in the UK

Our dedicated engineering team is ready to assist you in selecting the perfect bottle filling machine tailored to your specific production requirements.

We offer both modular and fully customised solutions to seamlessly integrate into your existing operations.

Contact us today to discuss your needs and discover how our Bottle Filling Machines can elevate your production efficiency and product quality.