Fruit Juice Filling Machines

Hygienic, accurate and versatile systems for fresh juice producers and contract packers.

We design and manufacture a wide range of liquid filling machines suitable for fruit juices, smoothies, nectars, and other beverages.

Whether you need a simple benchtop filler for small runs or a complete filling line for large-scale production, our UK-built machines deliver reliable performance and consistent results.

Designed for the Juice Industry.

Fruit juice production requires equipment that combines speed, accuracy, and hygiene. Our machines are built with food-grade stainless steel and are designed for easy cleaning, making them ideal for cold-pressed juices, pulpy blends, and concentrated syrups alike.

We support businesses at every stage of growth: from small-scale juice brands starting out, to contract packers running high-volume operations. All machines are engineered for precise, repeatable fills, reducing waste and helping you maintain the quality your customers expect.

We also offer options for integrating capping, labelling, induction sealing, and inspection systems—so you can expand from a standalone filler to a complete turnkey line as your production scales.

Hygienic, accurate and versatile systems for fresh juice producers and contract packers.

We design and manufacture a wide range of liquid filling machines suitable for fruit juices, smoothies, nectars, and other beverages.

Whether you need a simple benchtop filler for small runs or a complete filling line for large-scale production, our UK-built machines deliver reliable performance and consistent results.

Designed for the Juice Industry.

Fruit juice production requires equipment that combines speed, accuracy, and hygiene. Our machines are built with food-grade stainless steel and are designed for easy cleaning, making them ideal for cold-pressed juices, pulpy blends, and concentrated syrups alike.

We support businesses at every stage of growth: from small-scale juice brands starting out, to contract packers running high-volume operations. All machines are engineered for precise, repeatable fills, reducing waste and helping you maintain the quality your customers expect.

We also offer options for integrating capping, labelling, induction sealing, and inspection systems—so you can expand from a standalone filler to a complete turnkey line as your production scales.

Why Choose Our Juice Filling Machines?

Hygienic Design

All contact parts in 316 stainless steel, easy to clean.

Versatile Filling

Handles clear juices, pulpy blends, and smoothies.

Consistent Results

Accurate, repeatable fills from 5ml to 5 litres.

Scalable Systems

From benchtop units to fully automated lines.

Filling Machines for Fruit Juices

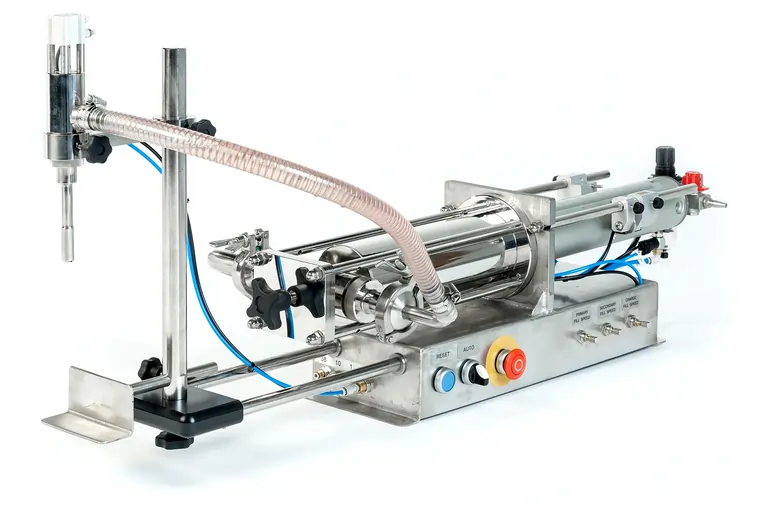

Posifill EF

Semi-automatic benchtop piston filler. Ideal for start-ups and small runs. Handles still juices and pulpy blends.

Posifill V-Twin

Twin-head or four-head free-standing volumetric fillers. Faster output, perfect for growing juice producers.

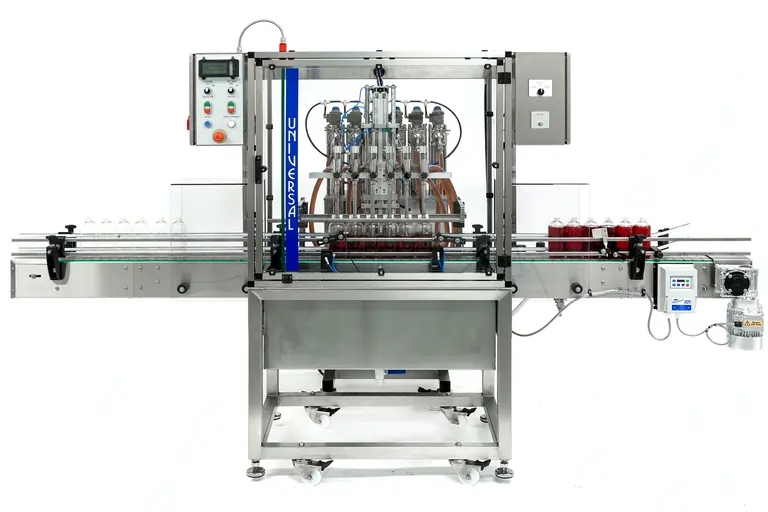

Posimatic EV1000

Fully automatic volumetric filling machine for higher-volume juice production. Combine it with an automatic capping machine and more to create an entire bottling line.

Posivac

Fully automatic vacuum filling machine for thinner juices into rigid plastic or glass bottles. Combine it with an automatic capping machine and more to create an entire bottling line.

How do volumetric filling machines work?

Piston fillers, such as the Posifill EF, Posifill V-Twin, P5000, and Posimatic EV1000, use a pneumatically-powered piston to draw liquid from a container into a cylinder via a feedpipe. The piston then pushes the liquid out through a metering valve into the bottle. Stroke length is fully adjustable across the fill range, offering excellent versatility.

Two types of metering valves are available:

– Ball & Spring valves – simple and low-cost, suited to thinner liquids but not ideal for thicker or pulpy products.

– Pneumatic Rotary valves – higher cost, but capable of handling almost any liquid, including viscous or particulate products.

This combination of precision, adjustability, and valve choice makes piston fillers among the most versatile filling technologies.

← Watch this explainer video to learn more.

How do vacuum filling machines work?

Vacuum fillers, like the Vacufill and Posivac, use compressed air to create a low-pressure zone inside the bottle. The nozzle’s sealing pad, forms an airtight fit around the bottle’s rim. Liquid is drawn up from the supply into the container, and filling stops automatically when the liquid reaches the vacuum tube inside the nozzle.

This system gives accurate, level fills, ideal for thin liquids and juices, and helps bottles look perfect for on-shelf presentation.

Adjustable settings make vacuum fillers versatile for different container sizes, making them ideal for small-batch and start-up production.

Watch this explainer video to learn more →

Suitable for a Wide Range of Fruit Juices

Our machines are used worldwide to fill:

-

Cold-pressed juices

-

Smoothies and pulpy blends

-

Concentrated syrups

-

Flavoured waters and nectars

-

Multi-pack juice shots

Whether you need precision for premium bottled juices or flexibility for contract packing, our machines adapt to your process.

Fruit Juice Filling Machines – FAQs

Can your machines handle fruit juices with pulp or seeds?

Yes. For juices containing pulp, fibres, or small seeds, we recommend our volumetric piston fillers (e.g. Posifill EF, Posifill V-Twin, P5000, or Posimatic EV1000). These should be specified with a pneumatically operated Rotary Valve, which allows particulates to pass through smoothly. The alternative Ball & Spring Valve is not suitable for pulpy or seeded liquids.

Are your machines suitable for hot filling fruit juices?

Yes. Our machines can be configured for hot-fill applications where pasteurisation is required. All liquid contact parts are manufactured from food- and pharmaceutical-grade 316 stainless steel, supplied with CE and UKCA conformity certification. Mill certificates can also be provided for customers who require full traceability of materials.

What filling speeds can I expect with fruit juice filling machines?

Filling speed depends on the machine type and number of heads. As a guide:

-

Semi-automatic machines: 10–30 bottles per minute (depending on fill size).

-

Automatic lines: up to 60+ bottles per minute.

For a detailed breakdown, see the Filling Machines Comparison Table below, which shows real-world throughput across our range.

Can I fill multiple bottle sizes with the same machine?

Yes, our machines are adjustable for different container sizes, but suitability depends on your production needs:

-

Up to 1 litre: Most machines in our range (e.g. Posifill EF, V-Twin, Posimatic EV1000) handle this very well.

-

Larger containers (up to 5 litres): The P5000 or Posimatic EV5000 are better suited, though large-volume fruit juice filling is less common.

We’ll always recommend the machine that balances flexibility with practical efficiency for your product range.

Do your machines meet food industry hygiene standards?

Yes. All contact parts are 316 stainless steel, designed for quick cleaning and full sanitation between runs. Every machine is supplied with CE and UKCA certification, and we can provide Mill Certificates for customers requiring detailed compliance documentation.

Can I start with a small machine and scale up production later?

Yes. Many juice producers begin with a semi-automatic filler and later expand to multi-head or fully automatic machines as demand grows. Because our semi-automatic range is built on a modular platform, production upgrades are straightforward and cost-effective, making scaling a real, practical option.

What types of containers can be filled with your machines?

Our machines can fill into PET, glass, and HDPE bottles, as well as other recyclable containers. One consideration: vacuum fillers require containers with a rim that can seal against our foam pad nozzle, and the container must be rigid enough to withstand vacuum pressure. For most other applications, volumetric fillers handle standard bottle types without issue.

Do you supply machines for juice concentrates or syrups?

Yes. Most of our volumetric fillers can be configured to handle viscous concentrates, syrups, and cordials, as well as ready-to-drink juices. For thinner, water-like liquids without pulp or particles, our vacuum filling machines are an excellent choice, with the right model depending on your required throughput and fill volumes.

How easy are your juice filling machines to clean between flavours?

Cleaning requirements depend on the machine type and valve configuration, but all are designed for straightforward sanitation. Volumetric fillers allow fast disassembly of contact parts for a thorough washdown, while vacuum fillers can be flushed through quickly for shorter changeovers. This minimises downtime when switching between different juice flavours.

Can your filling machines be integrated with capping and labelling equipment?

Yes. Our fillers can be paired with capping machines, labelling systems, induction sealing units, and inspection equipment to create a complete, turnkey bottling line. Integration is straightforward and scalable as your production expands.

Do you provide international support and spare parts?

Yes. We export worldwide and provide ongoing service, technical support, and readily available spare parts. Many of our machines are still in daily operation after decades of service thanks to our robust build quality and long-term support.

What are the typical lead times for a fruit juice filling machine?

Lead times vary by model and specification. Standard semi-automatic machines are often available on short lead times, while customised or automated filling systems may take longer to manufacture. We’ll confirm current availability when we discuss your project.

Suitable for a Wide Range of Fruit Juices

Our machines are used worldwide to fill:

-

Cold-pressed juices

-

Smoothies and pulpy blends

-

Concentrated syrups

-

Flavoured waters and nectars

-

Multi-pack juice shots

Whether you need precision for premium bottled juices or flexibility for contract packing, our machines adapt to your process.

Fruit Juice Filling Machines – FAQs

Can your machines handle fruit juices with pulp or seeds?

Yes. For juices containing pulp, fibres, or small seeds, we recommend our volumetric piston fillers (e.g. Posifill EF, Posifill V-Twin, P5000, or Posimatic EV1000). These should be specified with a pneumatically operated Rotary Valve, which allows particulates to pass through smoothly. The alternative Ball & Spring Valve is not suitable for pulpy or seeded liquids.

Are your machines suitable for hot filling fruit juices?

Yes. Our machines can be configured for hot-fill applications where pasteurisation is required. All liquid contact parts are manufactured from food- and pharmaceutical-grade 316 stainless steel, supplied with CE and UKCA conformity certification. Mill certificates can also be provided for customers who require full traceability of materials.

What filling speeds can I expect with fruit juice filling machines?

Filling speed depends on the machine type and number of heads. As a guide:

-

Semi-automatic machines: 10–30 bottles per minute (depending on fill size).

-

Automatic lines: up to 60+ bottles per minute.

For a detailed breakdown, see the Filling Machines Comparison Table below, which shows real-world throughput across our range.

Can I fill multiple bottle sizes with the same machine?

Yes, our machines are adjustable for different container sizes, but suitability depends on your production needs:

-

Up to 1 litre: Most machines in our range (e.g. Posifill EF, V-Twin, Posimatic EV1000) handle this very well.

-

Larger containers (up to 5 litres): The P5000 or Posimatic EV5000 are better suited, though large-volume fruit juice filling is less common.

We’ll always recommend the machine that balances flexibility with practical efficiency for your product range.

Do your machines meet food industry hygiene standards?

Yes. All contact parts are 316 stainless steel, designed for quick cleaning and full sanitation between runs. Every machine is supplied with CE and UKCA certification, and we can provide Mill Certificates for customers requiring detailed compliance documentation.

Can I start with a small machine and scale up production later?

Yes. Many juice producers begin with a semi-automatic filler and later expand to multi-head or fully automatic machines as demand grows. Because our semi-automatic range is built on a modular platform, production upgrades are straightforward and cost-effective, making scaling a real, practical option.

What types of containers can be filled with your machines?

Our machines can fill into PET, glass, and HDPE bottles, as well as other recyclable containers. One consideration: vacuum fillers require containers with a rim that can seal against our foam pad nozzle, and the container must be rigid enough to withstand vacuum pressure. For most other applications, volumetric fillers handle standard bottle types without issue.

Do you supply machines for juice concentrates or syrups?

Yes. Most of our volumetric fillers can be configured to handle viscous concentrates, syrups, and cordials, as well as ready-to-drink juices. For thinner, water-like liquids without pulp or particles, our vacuum filling machines are an excellent choice, with the right model depending on your required throughput and fill volumes.

How easy are your juice filling machines to clean between flavours?

Cleaning requirements depend on the machine type and valve configuration, but all are designed for straightforward sanitation. Volumetric fillers allow fast disassembly of contact parts for a thorough washdown, while vacuum fillers can be flushed through quickly for shorter changeovers. This minimises downtime when switching between different juice flavours.

Can your filling machines be integrated with capping and labelling equipment?

Yes. Our fillers can be paired with capping machines, labelling systems, induction sealing units, and inspection equipment to create a complete, turnkey bottling line. Integration is straightforward and scalable as your production expands.

Do you provide international support and spare parts?

Yes. We export worldwide and provide ongoing service, technical support, and readily available spare parts. Many of our machines are still in daily operation after decades of service thanks to our robust build quality and long-term support.

What are the typical lead times for a fruit juice filling machine?

Lead times vary by model and specification. Standard semi-automatic machines are often available on short lead times, while customised or automated filling systems may take longer to manufacture. We’ll confirm current availability when we discuss your project.

Compare Fruit Juice Filling Machines

| Model | Fill Volume Range | Maximum Speed | Filling Heads | Valve Type | Container Types | Format |

|---|---|---|---|---|---|---|

| Posifill EF | 5ml – 1,300ml | Up to 30 containers/min (1,800 containers/hour) | 1 | Rotary Valve or Ball & Spring | Bottles, jars | Benchtop |

| Vacufill | 10ml – 500ml (typical) | Up to 40 containers/min (2,400 containers/hour) | 1 or 2 | N/A (vacuum filling) | Glass & rigid plastic bottles, jars | Benchtop |

| Posifill V-Twin/Four | 5ml – 1,300ml | Up to 40 containers/min (2,400 containers/hour) | 2 or 4 | Rotary Valve or Ball & Spring | Bottles, jars | Free-standing |

| P5000 | 250ml – 5,000ml+ | Up to 15 containers/min (900 containers/hour) | 1 or 2 | Rotary Valve | Jerrycans, tubs, bottles | Free-standing |

| Posimatic EV1000 | 5ml – 1,300ml | Up to 100 containers/min (6,000 containers/hour) | 1, 2, 4, 6 ,8, 10 or 12 | Ball & Spring or Rotary Valve | Glass or plastic bottles, jars, etc. | Automatic | Posivac | 5ml – 1,000ml | Up to 80 containers/min (4,800 containers/hour) | 2 to 12 | N/A (vacuum filling) | Glass or plastic bottles, jars, etc. | Automatic |

| *Speeds are approximate and depend on fill volume, liquid characteristics, and operator efficiency. | ||||||

What do our customers say?

Talk to Us About Your Juice Filling Needs

Whether you’re launching a new juice product or scaling up production, we’ll help you find the right machine for your process. Tell us about your product and container type, and we’ll recommend the best solution.