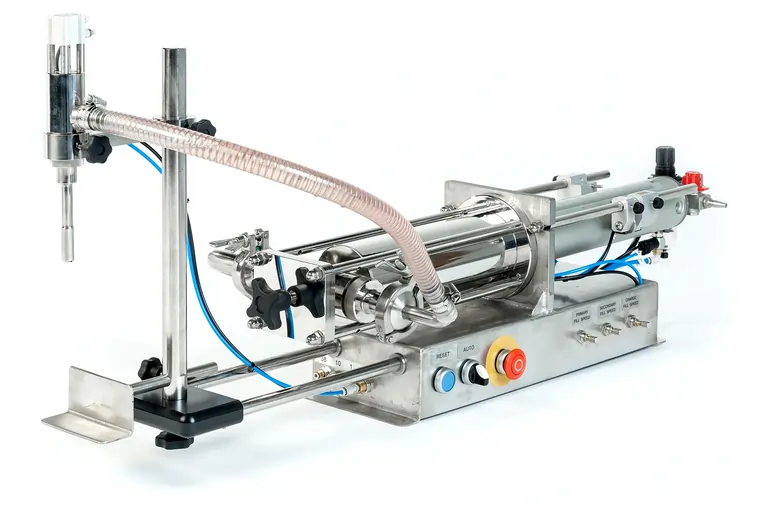

Posifill EF

Semi-Automatic Liquid Filling Machine:

Precision, Versatility and Efficiency

The Posifill EF is a high-performing semi-automatic filling machine, ideal for businesses seeking flexible, accurate, and efficient filling solutions.

Whether you’re new to using a liquid filling machine or need reliable equipment for growing production demands, the Posifill EF is designed to adapt to your needs.

Powered by compressed air, this robust filling machine is perfect for startups, small-scale operations, or as part of a larger production line. It delivers consistent performance, handling a variety of liquids from thin solvents to thicker creams, gels, and food products with particulates like fruit yogurts.

The Posifill EF can fill up to 30 containers per minute with precise volumetric accuracy. Its quick changeover design ensures minimal downtime, boosting productivity while maintaining exceptional quality.

Discover how the Posifill EF bottle filling machine can streamline your operations. Contact us today for more information on this versatile filling equipment and enhance your production capabilities with ease and confidence.

Filling Heads

1

Fill Volumes

5ml – 1,300ml

Speed

Up to 30 bottles per minute

Accuracy

Up to +/-0.5%

Filling Heads

1

Fill Volumes

5ml – 1,300ml

Speed

Up to 30 bottles per minute

Accuracy

Up to +/-0.5%

Posifill EF Features

Fills liquids, creams and gels

Small footprint for simple bench mounting

Quick release nozzle and feed pipe

Pneumatic operation suitable for hazardous areas

Future expandability – can be linked together and incorporated into fully automatic machine

Food and pharmaceutical quality 316 stainless steel contact parts

ATEX certified for filling flammable liquids

Tool free strip-down for easy cleaning

Easily accessible control panel mounted on the side of the machine

Foot pedal start for hands free operation

Ball & Spring or Rotary Valve options to suit any liquid

Feed pipes suitable for drawing from a barrel at floor level

Posifill EF Options & Extras

Pneumatically operated nozzles for drip free filling

Short stroke & full diving nozzle for bottom up filling

Spinning table for cream pots

Product hoppers & tanks in various sizes (heated versions also available)

Two speed fill & Auto-flushing/Auto-run controls

Heating elements & controllers for hot filling applications

Wide range of hose & seal materials to suit almost any liquid

What Our Customers Say

“Universal are our number one choice when we require a new filling machine …”

– Dale Eames, Production Manager, Vitax Limited

Quality and Service

Our customers range from start-up enterprises to exclusive, world-famous brands.

And, having built a worldwide client base after more than 45 years in business, we are proud that nearly 70% of our orders today are repeat business with existing customers, who rely on Universal Filling Machine Company to provide them with first class support and help them grow their businesses.

Every single machine or system we sell is 100% tested in our production facility to ensure it meets the customer’s requirements and performance targets.

Request further information about the Posifill EF semi-automatic liquid filling machine

Our machines are designed to be highly versatile and adaptable, but as no two customers are the same, we have a large technical department offering you a bespoke solution to meet your exact requirements and ensure they’re ready to evolve as your business grows.

Our engineers will work with you to meet your exact requirement now and in the future.

Frequently Asked Questions

What is the Posifill EF best suited for?

The Posifill EF is a compact benchtop filler designed for small-batch production. It’s highly accurate and easy to use, making it popular for startups, laboratories, and niche producers.

Over its 40+ years of production, it has become the industry standard for small-scale piston filling.

Why is the Posifill EF so well-regarded in the industry?

The Posifill EF has earned its reputation through decades of reliable service. It is widely imitated by competitors, but the genuine Posifill continues to set the benchmark for quality. Many units are still running after decades of daily use, a testament to its durability.

This reputation has made the name “Posifill” synonymous with piston fillers across many sectors.

What liquids can the Posifill EF handle?

The Posifill EF is versatile, capable of filling thin liquids, viscous products, and even those containing small particulates. Its piston-driven accuracy ensures consistent volumes across every fill.

This makes it suitable for industries ranging from cosmetics to chemicals, food, and pharmaceuticals.

How does the Posifill EF compare to low-cost alternatives?

Cheaper machines often fail to meet UK/EU safety and hygiene standards and can prove unreliable in production. In contrast, the Posifill EF is fully compliant, durable, and engineered for commerical use.

While the upfront cost is higher, the long-term savings in reliability, safety, and reduced downtime make it a far better investment.