Capping Machines

Universal Filling Machine Company manufactures and supplies a range of capping machines to suit a wide range of bottles, caps and closures.

We offer solutions for various cap types including pre-threaded screw caps, ROPP caps, valve crimping, and press-on caps.

In need of optimising your bottling process and enhancing productivity? Our diverse capping machinery lineup comprises automatic and semi-automatic capping machines, tailored to meet your specific needs. If you don’t find a suitable machine in our standard range, reach out to us to discuss your unique requirements. Our engineering team is ready to explore modifications or even custom machine designs tailored to your needs.

Our Capping Machines are for high speed applications and include conveyors and electro/pneumatic PLC controls

The reliability and precision of Universal’s automatic capping machines make them indispensable assets for businesses across various sectors. From pharmaceuticals to food and beverage industries, these machines offer a versatile solution to bottle capping requirements, accommodating different bottle sizes and cap types with ease. Not only do Universal’s capping machines improve productivity by automating the capping process, but they also uphold the highest standards of quality.

These automatic capping machines can cap or close bottles in the 5ml to 10 litre fill range. Outputs range from 20 to 60 bottles per minute (1,200-3,600/hour).

Reliable Capping Machines for Every Bottle and Cap

Looking for a fast, efficient way to seal your bottles?

Universal Filling Machine Company offers a wide range of automatic capping machines to suit:

Pre-Threaded Screw Caps • ROPP Caps

Press-On Caps • Valve Crimp Closures

Our Capping Machines are for high speed applications and include conveyors and electro/pneumatic PLC controls

The reliability and precision of Universal’s automatic capping machines make them indispensable assets for businesses across various sectors. From pharmaceuticals to food and beverage industries, these machines offer a versatile solution to bottle capping requirements, accommodating different bottle sizes and cap types with ease. Not only do Universal’s capping machines improve productivity by automating the capping process, but they also uphold the highest standards of quality.

Our Capping Machines are for high speed applications and include conveyors and electro/pneumatic PLC controls

The reliability and precision of Universal’s automatic capping machines make them indispensable assets for businesses across various sectors. From pharmaceuticals to food and beverage industries, these machines offer a versatile solution to bottle capping requirements, accommodating different bottle sizes and cap types with ease. Not only do Universal’s capping machines improve productivity by automating the capping process, but they also uphold the highest standards of quality.

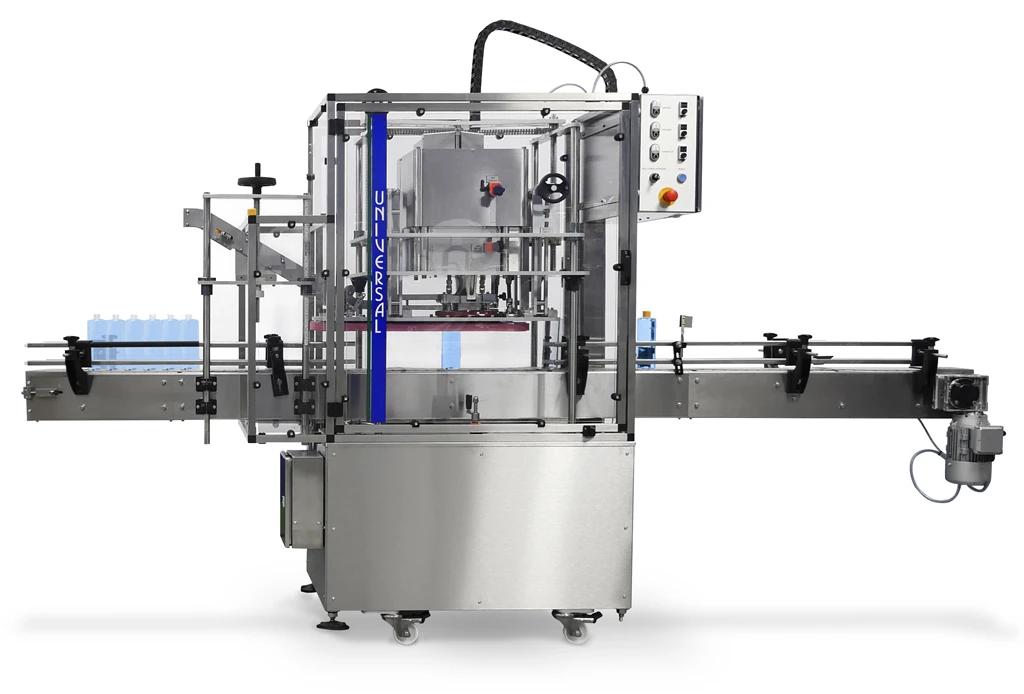

Universal Belt Capper

Automatic Screw Capping Machine

A versatile automatic capping machine handling screw caps from 20–120mm diameter. Achieves up to 60 bottles per minute with tool-free changeovers and consistent torque control.

Typical cap types:

Posicap ROPP

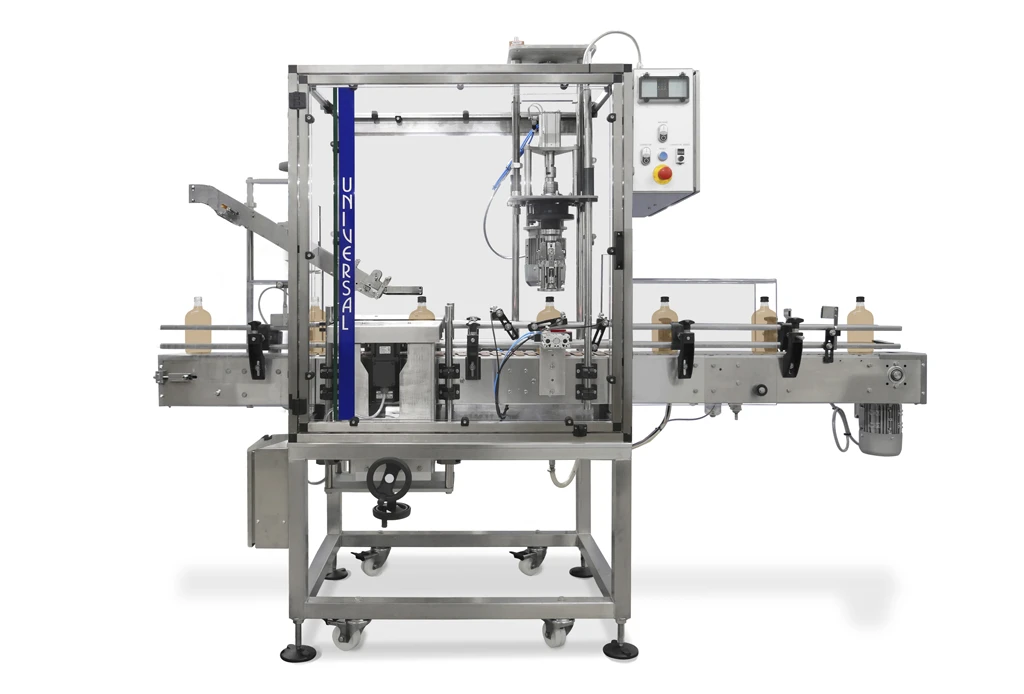

Automatic ROPP Capping Machine

Designed for roll-on pilfer-proof caps, this machine handles 18–38mm caps at speeds up to 60 bottles per minute. Ideal for tamper-evident sealing in food and beverage industries.

Typical cap types:

Posicap

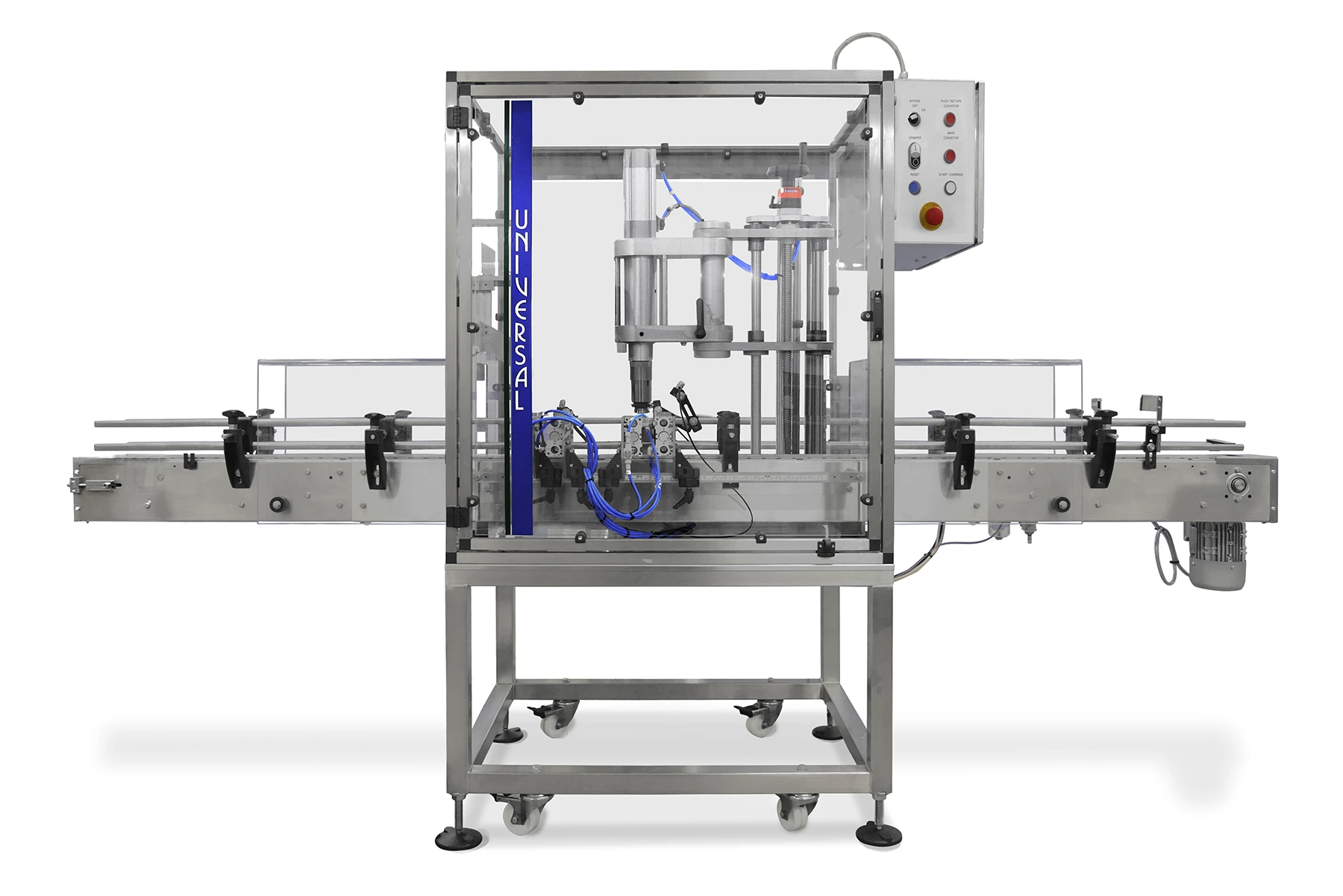

Automatic Capping Machine

An automatic capping solution for screw, ROPP, crimp, and press-on caps. Operates at up to 30 bottles per minute with adjustable torque and quick-change jaws.

Typical cap types:

Posicrimp

Automatic Capping Machine

Specialized for crimping perfume and pharmaceutical vial caps ranging from 11–20mm. Offers single or dual-head operation with speeds up to 60 bottles per minute.

Typical cap types:

Seamless Integration with Filling Machines

An automatic capping machine from Universal can be easily integrated with our automatic filling machines or adapted to work with other manufacturers’ equipment. Our systems include conveyors and electro/pneumatic PLC controls.

This flexibility makes our capping equipment a versatile addition to any production line, streamlining operations and simplifying workflow management.

Universal’s automatic capping machines are compatible with various cap feeding systems, including Vibrating Bowl Feeders and Pick and Place systems. Caps can also be manually placed, offering even more adaptability. No matter the setup, our capping machines ensure consistent, secure closures for every bottle.

Capping Machines Quick Comparison Table

Machine

Speed

Cap Size

Bottle Size

Cap Torque

Cap Types

Universal Belt Capper

Up to 60/minute

20-120mm diameter

20-120mm diameter x

50-300mm height

Up to 10Nm

Screw Caps, Trigger Sprays, Pump Sprays, Push-Pull Caps, Flip-Top Caps, Tamper Evident Caps & more.

Posicap

Up to 30/minute

8-100mm diameter

15-200mm diameter x

up to 400mm height

Up to 5Nm

Child-Resistant Caps, Screw Caps, Pump Sprays, Push-Pull Caps, Flip-Top Caps, Tamper Evident Caps & more.

Posicap ROPP

Up to 60/minute

18-38mm diameter

15-200mm diameter x

up to 400mm height

N/A

Roll-On-Pilfer Proof Caps

Posicrimp

Up to 60/minute

11, 13, 15, 17, 18 & 20mm

20-200mm diameter x

up to 400mm height

N/A

Crimped Caps, Pump Sprays, Septum Caps & similar

Quality & Service

Our customers range from start-up enterprises to exclusive, world-famous brands.

At Universal Filling Machine Company, quality is our top priority. Each of our capping machines is crafted with precision and built to withstand rigorous use, guaranteeing long-lasting performance and minimal downtime.

We pride ourselves in manufacturing the highest quality products and supporting our customers with outstanding service. And, having built a worldwide client base after more than 45 years in business, we are proud that nearly 70% of our orders today are repeat business with existing customers, who rely on Universal Filling Machine Company to provide them with first class support and help them grow their businesses.

Every single machine or system we sell is 100% tested in our production facility to ensure it meets the customer’s requirements and performance targets. Don’t settle for subpar capping solutions. Choose Universal Filling Machine Company for high-quality capping machines that improve productivity and deliver fantastic results every time.

Request further information about our range of capping machines

Our customers range from startups to globally recognised brands, all relying on our high-quality capping equipment.

With over 45 years of industry experience, Universal Filling Machine Company is proud that nearly 70% of our orders come from repeat customers who trust us for dependable machines and outstanding service.

Each capping machine we manufacture undergoes rigorous in-house testing to ensure it meets your exact performance requirements.

We build our machines to last, minimising downtime and delivering reliable, long-term results.

Choose Universal Filling Machine Company for high-performance automatic capping machines and expert support that helps your business thrive.

Contact us today to discuss your capping machinery needs and discover the perfect solution for your production line.