Automatic Liquid Filling Machines for Every Industry

Automatic Liquid Filling Machines You Can Rely On

Since 1976, Universal Filling Machine Company has been designing and building automatic liquid filling machines in the UK. Our machines are trusted across industries to fill liquids safely, efficiently, and accurately — from chemicals and industrial liquids to food products and high-viscosity sauces.

With options like multi-head configurations, corrosion-resistant stainless steel contact parts, and ATEX-ready designs for flammable liquids, our filling machines combine reliability with flexibility. Modular features allow seamless integration with capping, labelling, and inspection systems, making it easy to create a complete, tailored filling solution for your production line.

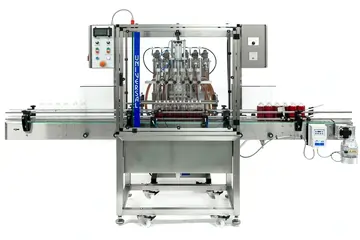

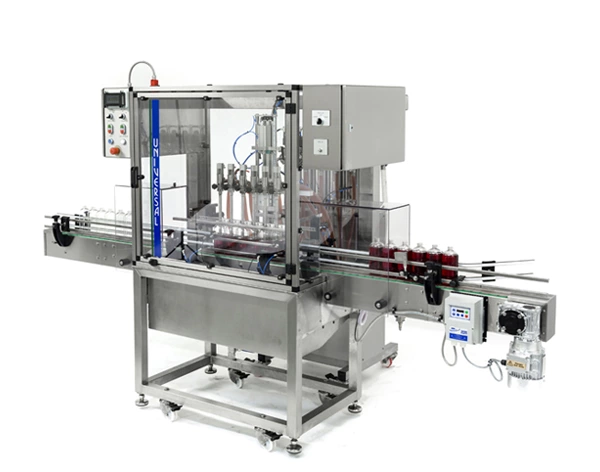

Posimatic EV1000

2, 4, 6, 8 or 12 Head Automatic Volumetric Liquid Filling Machine/Bottling Machine

Speed: Up to 120 bottles per minute

Filling Range: 5ml – 1,3000ml

Key Benefits

Handles a wide range of bottle sizes and shapes with minimal adjustments.

Quick, tool-free changeovers reduce downtime.

Durable UK-built stainless steel contact parts for hygiene and longevity.

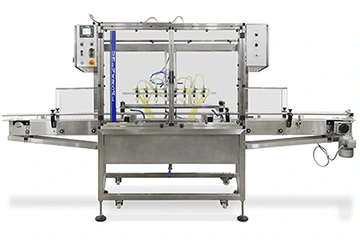

Posimatic EV2500

2, 4, 6 or 8 Head Automatic Volumetric Liquid Filling Machine/Bottling Machine

Speed: Up to 60 bottles per minute

Filling Range: 100ml – 2,500ml

Key Benefits

Mid-capacity solution suitable for low- to medium-viscosity liquids.

Modular design allows easy integration with capping/labeling systems.

Continuous operation reduces operator involvement and product waste.

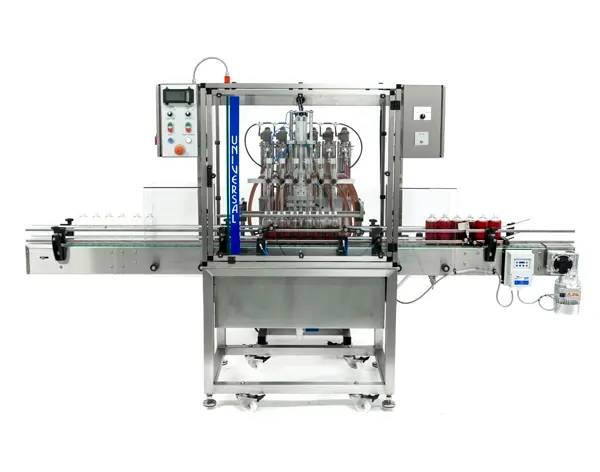

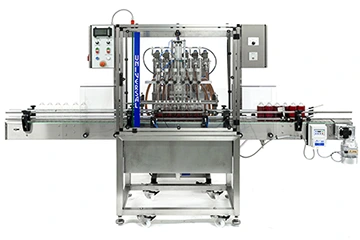

Posimatic EV5000

2, 4 or 6 Head Automatic Volumetric Liquid Filling Machine/Bottling Machine

Speed: Up to 120 bottles per minute

Filling Range: 5ml – 5,000ml (typical)

Key Benefits

High-volume production with consistent, accurate fills.

Heavy-duty construction for demanding industrial use.

Minimises operator supervision for large-scale bottling.

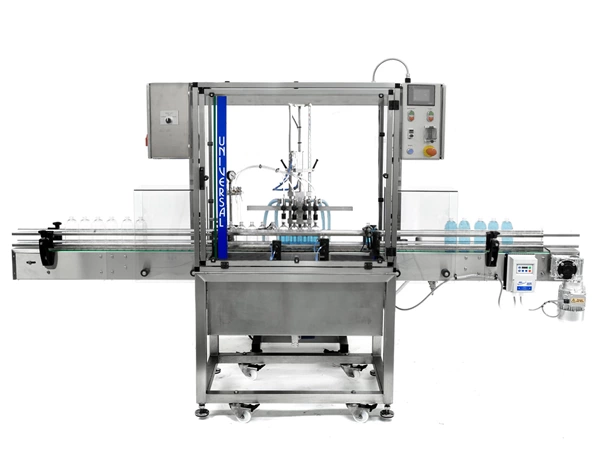

NEW Posimatic EVL

2 to 8 Head Automatic Liquid Filling Machine

Speed: Up to 60 bottles/minute

Fill Range: 5ml – 5,000ml (model dependant)

Key Benefits

Fully automated line for a variety of liquid viscosities.

Easy integration with infeed and outfeed conveyors.

Designed for long-term UK support and maintenance.

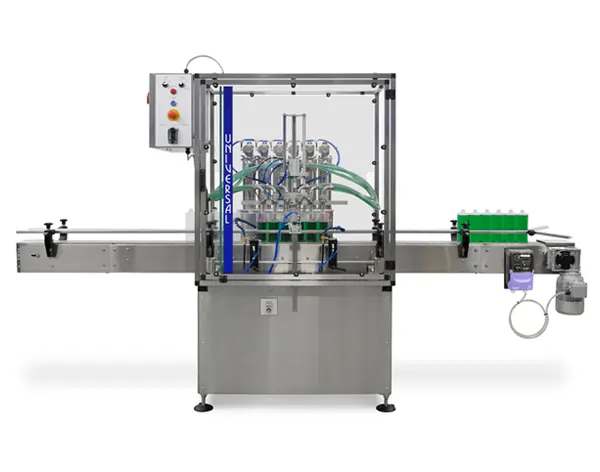

Posimatic Voluvac

2 to 12 Head Automatic Volumetric/Vacuum Level Liquid Filling Machine

Speed: Up to 120 bottles per minute

Filling Range: 5ml – 5,000ml (typical)

Key Benefits

Combines volumetric and vacuum-level filling for maximum versatility.

Covers a wide range of liquid types, reducing the need for multiple machines.

Supports turnkey production lines for high-efficiency operations.

All of our automatic filling machines can be combined with any of our automatic capping machines to create a fully automatic filling and capping machine, along with a variety of other functions such as labelling or sleeving.

At Universal Filling Machine Company, we prioritise innovation, quality, and reliability, ensuring that our filling machines are built to the highest standards and using the highest quality materials to meet the evolving needs of modern manufacturing.

Trust us to deliver reliable, high-performance filling solutions that will elevate your production processes to new heights and provide outstanding service for years to come.

Contact us today on +44 (0)1233 643666 to learn more about our automatic filling machines and how they can benefit your business, or enter your contact details below and one of our sales team will contact you.

All of our automatic filling machines can be combined with any of our automatic capping machines to create a fully automatic filling and capping machine, along with a variety of other functions such as labelling or sleeving.

At Universal Filling Machine Company, we prioritise innovation, quality, and reliability, ensuring that our filling machines are built to the highest standards and using the highest quality materials to meet the evolving needs of modern manufacturing.

Trust us to deliver reliable, high-performance filling solutions that will elevate your production processes to new heights and provide outstanding service for years to come.

Contact us today on +44 (0)1233 643666 to learn more about our automatic filling machines and how they can benefit your business, or enter your contact details below and one of our sales team will contact you.

Request further information about Automatic Filling Machines

Automatic Liquid Filling Machines You Can Rely On

Universal Filling Machine Company designs and manufactures versatile automatic liquid filling machines suitable for every industry. From low- to high-viscosity liquids, our UK-built systems offer precision, reliability, and flexibility.

Modular designs make integration with capping, labelling, and sealing equipment simple; creating turnkey production lines tailored to your needs.

Posimatic EV1000

2, 4, 6, 8 or 12 Head Automatic Volumetric Liquid Filling Machine/Bottling Machine

Speed: Up to 100 bottles per minute | Filling Range: 5ml – 1,300ml

Key Benefits

Handles a wide range of bottle sizes and shapes with minimal adjustments.

Quick, tool-free changeovers reduce downtime.

Durable UK-built stainless steel contact parts for hygiene and longevity.

Posimatic EV2500

2, 4, 6 or 8 Head Automatic Volumetric Liquid Filling Machine/Bottling Machine

Speed: Up to 60 bottles per minute | Filling Range: 100ml – 2,500ml

Key Benefits

Mid-capacity solution suitable for low- to medium-viscosity liquids.

Modular design allows easy integration with capping/labeling systems.

Continuous operation reduces operator involvement and product waste.

Posimatic EV5000

2, 4 or 6 Head Automatic Volumetric Liquid Filling Machine/Bottling Machine

Speed: Up to 40 bottles per minute | Filling Range: 250ml – 5,000ml

Key Benefits

High-volume production with consistent, accurate fills.

Heavy-duty construction for demanding industrial use.

Minimises operator supervision for large-scale bottling.

Our automatic liquid filling machines deliver precision, speed, and flexibility.

Posimatic volumetric machines provide accurate, repeatable fills for liquids of varying viscosities, helping you maintain consistent product quality and reduce waste.

The Posivac vacuum level filling machine is ideal for thinner liquids, drawing liquid under vacuum for a consistent fill height — perfect for rigid bottles displayed side-by-side.

Posimatic Voluvac combines volumetric and vacuum-level technology in a single modular machine, giving you the flexibility to handle multiple liquid types without changing equipment.

All our machines are designed for reliable, high-speed production, easy cleaning, and long-term durability. They integrate seamlessly into automated bottling lines, making them a smart choice for growing businesses and large-scale production alike. Take a look at our entire liquid filling machines range

NEW Posimatic EVL

2 to 8 Head Automatic Liquid Filling Machine

Speed: Up to 60 bottles/minute | Fill Range: 5ml – 5,000ml (model dependant)

Key Beneftits

Fully automated line for a variety of liquid viscosities.

Easy integration with infeed and outfeed conveyors.

Designed for long-term UK support and maintenance.

Posivac

2 to 12 Head Automatic Liquid Filling Machine

Speed: Up to 80 bottles per minute | Filling Range: 2ml – 1,500ml

Key Beneftits

Vacuum-level filling for consistent fill heights.

Ideal for clear glass bottles on retail display.

Can be integrated into turnkey automatic production lines.

Posimatic Voluvac

2 to 12 Head Automatic Volumetric/Vacuum Level Liquid Filling Machine

Speed: Up to 120 bottles/min | Filling Range: 5 ml – 5,000 ml (typical)

Key Beneftits

Combines volumetric and vacuum-level filling for maximum versatility.

Covers a wide range of liquid types, reducing the need for multiple machines.

Supports turnkey production lines for high-efficiency operations.

All of our automatic filling machines can be combined with any of our automatic capping machines to create a fully automatic filling and capping machine, along with a variety of other functions such as labelling or sleeving.

At Universal Filling Machine Company, we prioritise innovation, quality, and reliability, ensuring that our filling machines are built to the highest standards and using the highest quality materials to meet the evolving needs of modern manufacturing.

Trust us to deliver reliable, high-performance filling solutions that will elevate your production processes to new heights and provide outstanding service for years to come.

Contact us today on +44 (0)1233 643666 to learn more about our automatic filling machines and how they can benefit your business, or enter your contact details below and one of our sales team will contact you.

Request further information about Automatic Filling Machines

Quality & Service

Our customers range from start-up enterprises to exclusive, world-famous brands.

We pride ourselves in manufacturing the highest quality products and supporting our customers with outstanding service. And, having built a worldwide client base after more than 45 years in business, we are proud that nearly 70% of our orders today are repeat business with existing customers, who rely on Universal Filling Machine Company to provide them with first class support and help them grow their businesses.

Every single machine or system we sell is 100% tested in our production facility to ensure it meets the customer’s requirements and performance targets.

Frequently Asked Questions

What makes an automatic liquid filling machine different from a semi-automatic one?

Automatic liquid filling machines integrate conveyors, multiple fill heads, sensors, and control systems to fill containers without constant operator input. This enables higher production speeds, consistent accuracy, and reduced labor costs compared to semi-automatic machines.

Also see How Does An Automatic Filling Machine Work?

What production speeds can I expect from automatic filling machines?

Automatic machines like the Posimatic EV1000, EV2500, and Voluvac can fill anywhere from 40 to 120 bottles per minute depending on the model, number of heads, fill volume, and liquid type. Speeds are adjustable to suit different container sizes and viscosities.

Can automatic filling machines handle different bottle sizes and shapes?

Yes. Automatic systems can be configured with adjustable fill heads, nozzles, and conveyors to handle a wide variety of container sizes, from small vials to large 5-litre bottles. Some models even support changeovers without tools for maximum flexibility.

Are automatic liquid filling machines suitable for viscous or foamy liquids?

Absolutely. Volumetric systems can fill thin liquids, viscous sauces, creams, and even foaming products. Choosing the correct filling method ensures consistent fills and minimal waste.

How easy is it to clean and maintain automatic filling machines?

Automatic machines are designed with hygiene and efficiency in mind. Stainless steel contact parts, quick-release nozzles, and CIP (clean-in-place) options make cleaning fast and simple. Regular maintenance ensures long-term accuracy and reliability.

Can automatic liquid filling machines be integrated into a complete production line?

Yes. Automatic fillers can be combined with cappers, labelers, checkweighers, and induction sealers to create a fully automated bottling line. Integration reduces manual handling, increases throughput, and ensures consistent product quality.

Are automatic filling machines suitable for hazardous or corrosive liquids?

Yes. With appropriate materials (e.g., stainless steel, chemical-resistant seals) and safety features, automatic machines can safely handle aggressive liquids such as solvents, acids, or chemicals. Universal can advise on the right configuration for your product.

How do I select the right automatic filling machine for my production needs?

Consider your target fill volume, bottle size, liquid type, and production speed. For high-speed operations with multiple product lines, models like the Posimatic EV5000 or Voluvac may be ideal. Universal can provide expert guidance, technical data, and trial fills to ensure the chosen machine meets your requirements.

Why Choose Universal Filling Machine Company?

50+ Years’ Experience as an Industry Leader

Built Using the Highest Quality Components and Materials

Machines Can Be Specified To Suit Almost Any Liquid

Outstanding Customer Service

Customers in Over 80 Countries Around the World

Designed and Manufactured in the UK

Compare Automatic Liquid Filling Machines

| Model | Fill Volume Range | Maximum Speed | Filling Heads | Valve Type | Container Types | Format |

|---|---|---|---|---|---|---|

| Posimatic EV1000 | 5ml – 1,300ml | Up to 120 containers/min | 2, 4, 6, 8 or 12 | Rotary Valve or Ball & Spring | Bottles, jars | Inline Automatic with Conveyor |

| Posimatic EV2500 | 100ml – 2,500ml | Up to 60 containers/min | 2, 4, 6 or 8 | Rotary Valve or Ball & Spring | Bottles, jars, tubs | Inline Automatic with Conveyor |

| Posimatic EV5000 | 250ml – 5,000ml | Up to 30 containers/min | 2, 4 or 6 | Rotary Valve or Ball & Spring | Jerrycans, tubs, bottles | Inline Automatic with Conveyor |

| Posimatic EVL | 5ml – 5,000ml (model dependent) | Up to 60 containers/min | 1, 2, 4, 6 or 8 | Rotary Valve or Ball & Spring | Bottles, jars, jerrycans, tubs, vials | Inline Automatic with Conveyor |

| Posivac | 2ml – 1,500ml | Up to 80 containers/min | 2 to 12 | N/A (vacuum filling) | Glass & rigid plastic bottles, jars | Inline Automatic with Conveyor |

| Posimatic Voluvac | 5ml – 5,000ml (typical) | Up to 120 containers/min | 2 to 12 | Rotary Valve & Vacuum Filling | Bottles, jars, jerrycans, tubs, pails | Inline Automatic with Conveyor |

| *Speeds are approximate and depend on fill volume, liquid characteristics, and operator efficiency. | ||||||