An automatic filling machine is a vital part of any efficient packaging line, offering fast, precise, and hygienic liquid dispensing across a wide range of industries.

Whether you’re packaging pharmaceuticals, cosmetics, food, beverages, or chemicals, an automatic bottle filling machine can significantly increase throughput, reduce waste, and ensure consistent product quality.

Universal Filling Machine Company specialises in British-built, high-quality automatic liquid filling machines, supporting businesses worldwide with reliable equipment tailored to their unique production needs.

What Is an Automatic Liquid Filling Machine?

An automatic liquid filling machine is designed to dispense measured volumes of liquid into containers without the need for manual intervention.

These machines can operate continuously in production environments, automatically managing container handling, filling, and—when integrated—capping and labelling.

These systems are part of a complete liquid filling system, which may include bottle feeding, filling, cap placement, sealing, and coding—all synchronised to maximise productivity.

Types of Automatic Filling Machines

Universal Filling Machine Company offers two main types of automatic filling systems: volumetric piston filling and vacuum filling. Each is optimised for different product characteristics and container types.

Volumetric Piston Filling Machines

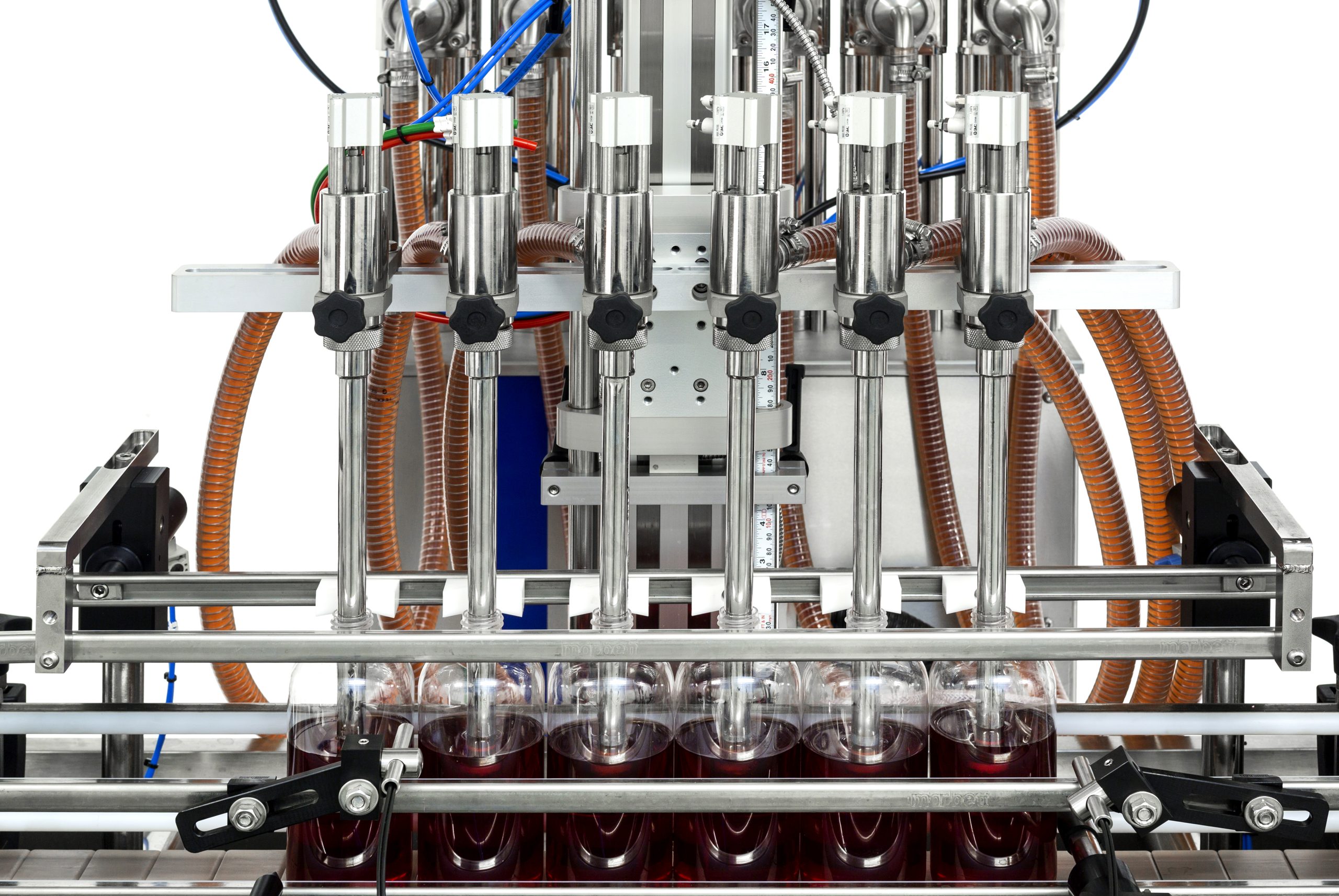

Our volumetric piston filling machines are among the most versatile solutions available. These machines use pneumatically or mechanically operated pistons to draw and dispense liquid in highly controlled volumes.

Unlike flow meter-based systems, piston fillers are ideal for both low and high-viscosity products. They can handle:

-

Thin liquids like oils and sanitisers

-

Viscous products such as creams, shampoos, sauces, and gels

-

Products with particulates, like soups or fruit preparations

Available in semi-automatic and fully automatic configurations (like the Posimatic EV1000, EV2500, and EV5000), these machines support fill volumes from as low as 5ml to over 5 litres, with exceptional accuracy (typically ±0.5%).

Vacuum Filling Machines

Vacuum filling is ideal for thin, free-flowing liquids such as perfumes, toners, and light oils, particularly when filling into rigid containers like glass bottles.

It works by using a vacuum to draw liquid into each container until it reaches a consistent level.

This method is extremely clean and precise, minimising foaming and ensuring a consistent fill height—particularly important for retail presentation. Universal’s Posivac machine is a robust, hygienic solution for vacuum-based filling lines.

How Does an Automatic Filling System Operate?

An automatic filling system typically works in a continuous, synchronised process:

- Container Infeed – Empty bottles or jars are fed into the system via a conveyor.

- Indexing & Positioning – Containers are aligned and held in position under the filling nozzles.

- Filling Cycle – Product is dispensed using piston or vacuum technology, depending on the system type.

Nozzle Retraction – In piston systems, the nozzles may dive into the container and retract (bottom-up filling) to prevent splashing or foaming.

Container Discharge/Outfeed – Filled containers are released for capping, labelling, or further processing.

Advanced systems offer touch-screen HMI controls, recipe storage, tool-free changeovers, and integration with ancillary equipment such as automatic capping machines (e.g., the Posicap or Universal Belt Capper).

Key Benefits of Automatic Bottle Filling Machines

-

Increased productivity and output consistency

-

Accurate dosing and reduced product waste

-

Improved hygiene and reduced contamination risk

-

Minimised operator involvement and manual error

-

Scalable for future growth

Why Choose Universal Filling Machine Company?

With over 50 years of engineering excellence, Universal offers:

-

Modular systems tailored to your needs

-

Machines suitable for hazardous environments (ATEX-certified options)

-

Support for both small-scale operations and high-speed production lines

-

A global customer base and proven reliability

Explore our full range of automatic filling machines or speak with our experts to find the ideal liquid filling solution for your business.

Automatic Liquid Filling Machines

Fast. Precise. Hygienic.

Built for Productivity.

Automatic filling machines are essential for efficient packaging lines—offering fast, accurate, and hygienic liquid dispensing across a wide range of industries.

From pharmaceuticals and cosmetics to food, beverages and chemicals, these machines can:

• Boost throughput

• Reduce waste

• Ensure consistent product quality

Universal Filling Machine Company specialises in British-built automatic filling machines, trusted worldwide for performance and reliability.

What Is an Automatic Liquid Filling Machine?

An automatic liquid filling machine dispenses precise amounts of liquid into containers—no manual work needed.

Once installed, it handles:

• Container feeding

• Positioning

• Filling

• (Optional) Capping, labelling & coding

Everything works together to maximise speed, hygiene and efficiency.

Types of Automatic Filling Machines

We offer two core systems, each optimised for different liquids and containers:

Volumetric Piston Fillers

Versatile & accurate—ideal for most applications

• Uses pistons to fill exact volumes

• Works with thin or thick liquids

• Handles solids or particulates (e.g. fruit bits, soups)

Great for:

• Oils & sanitisers

• Creams, shampoos & gels

• Sauces, pastes & ready meals

Fill range: 5ml to 5+ litres • Accuracy: ±0.5%

Vacuum Filling Machines

Clean, consistent fills—ideal for clear rigid plastic or glass containers

• Uses vacuum suction to fill to a set liquid level

• Prevents foam & spillage

• Especially good for retail-ready appearance

Best for:

• Perfumes

• Toners

• Light oils

How It Works: The Automatic Filling Process

Here’s what a typical system does—start to finish:

Infeed.

Empty bottles fed via conveyor

Positioning.

Each bottle stops under a filling nozzle

Filling.

Liquid is dispensed via piston or vacuum

Nozzle Movement.

Bottom-up filling avoids splashing (piston only)

Outfeed.

Filled bottles exit for capping, labelling or sealing

Optional features include:

• Touchscreen HMI

• Recipe memory

• Tool-free changeovers

• Integration with cappers like Posicap or the Universal Belt Capper

Key Benefits

• Faster production

• Consistent dosing

• Hygienic operation

• Fewer manual errors

• Ready for future growth

Why Choose Universal?

With over 50 years of engineering expertise, we offer:

• Modular filling systems tailored to your needs

• ATEX-certified options for hazardous products

• Support for small batch runs or full-scale production

• Proven performance, trusted by clients worldwide

📞 Not sure what you need?

Explore our range or talk to our experts for guidance on the best solution for your business.

Request further information about our filling machines