A ROPP capping machine, also known as a Roll-On Pilfer-Proof capping machine, is a piece of equipment used in the packaging industry to seal bottles and containers with aluminium caps.

ROPP capping systems are commonly used in industries such as pharmaceuticals, beverages, cosmetics, and chemicals.

An ROPP capping machine is designed to seal bottles securely and tightly, providing a tamper-evident closure that ensures product integrity. The name “Roll-On Pilfer-Proof” describes the mechanism by which the cap is applied to the bottle.

The machine applies downward pressure while simultaneously rotating forming wheels around the cap, causing the skirt of the cap to roll onto the bottle neck and replicate its screw thread. This action creates a strong seal that is difficult to remove without visible evidence of tampering.

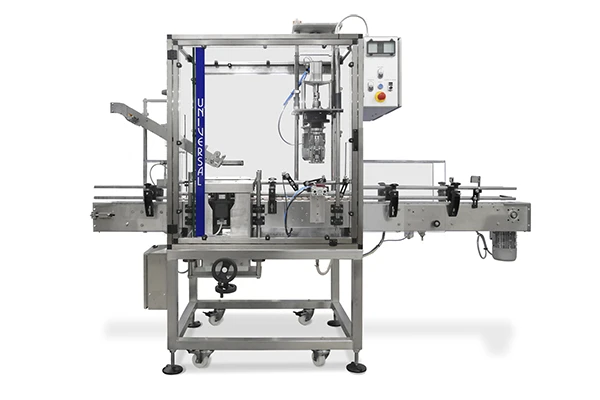

An automatic ROPP capping machine typically consists of a conveyor system that transports the bottles, a cap sorting and feeding mechanism, and the capping head, although semi-automatic variants are also available, such as our compact and economical benchtop ROPP Capping Machine, which requires the operator to position caps and bottles and operate the machine via two buttons.

The capping head is equipped with rollers that engage with the cap and apply the necessary pressure and rotational motion to secure it onto the bottle.

These machines are often automated, capable of handling a high volume of bottles in a continuous production line. They can be integrated into packaging lines alongside other equipment such as bottle filling machines, labelling machines, and induction sealers to create a complete packaging system.

Semi-automatic ROPP capping machines are ideal for small-scale bottling operations and require a smaller investment and less space than fully automated filling and capping lines, although production output is substantially lower and more labour-intensive.

What Are The Advantages Of ROPP Capping Machines?

Secure and Tamper-Evident Sealing: ROPP capping machines are renowned for providing a secure and tamper-evident seal. The rolling action of the cap onto the bottle neck creates a tight and robust closure, minimizing the risk of leaks, contamination, or product spoilage. The tamper-evident feature ensures that consumers can easily identify if a product has been tampered with or compromised.

Versatility: ROPP capping machines can handle a wide range of bottle sizes, shapes, and materials. Whether it’s glass or plastic containers, various diameters, or different neck finishes, these machines can be adjusted to accommodate different packaging requirements. This flexibility makes them suitable for diverse industries such as pharmaceuticals, beverages, cosmetics, and chemicals.

High Production Efficiency: ROPP capping machines are designed for high-speed operation, making them ideal for large-scale production. With automated capabilities, they can seamlessly integrate into packaging lines, working in synchronization with other equipment to maintain a smooth and efficient production flow. This efficiency helps to optimize productivity and minimize downtime.

Easy Integration: ROPP capping machines can be easily integrated into existing packaging lines or used as standalone equipment. They are compatible with conveyor systems, allowing bottles to be smoothly transported through the capping process. The machines can also be synchronized with other machinery, such as bottle filling machines, to create a complete and integrated packaging solution.

Operation of an automatic ROPP Capper

The operation of an automatic ROPP capping machine typically involves the following steps:

Bottle Placement: Empty bottles are placed onto the conveyor system, either manually or automatically, which carries them through the capping process.

Cap Sorting and Feeding: Caps are sorted and fed into the capping machine using a cap feeder or elevator. This mechanism ensures a continuous supply of caps to the capping head.

Cap Placement: The capping head positions the cap above the bottle neck and aligns it correctly for the capping process.

Capping Process: The capping head descends, applying downward pressure while simultaneously rotating the cap. This rolling action causes the threaded skirt of the cap to engage with and seal onto the bottle neck.

Bottle Release: Once the cap is securely applied, the capping head is raised, and the bottle continues along the conveyor for further processing or packaging.

Operation of a semi-automatic ROPP Capper

The operation of a semi-automatic ROPP capping machine typically involves these steps:

Cap Placement: Caps are hand placed onto filled bottles.

Positioning: The bottle and cap are placed into the semi-automatic ROPP Capping Machine and located against a fixture or end stop to ensure they are correctly positioned for the Capping Head.

Machine Operation: Two buttons must be simultaneously pressed – for safety – and held during the ROPP cap forming process

Capping Process: The ROPP Capping Head starts to spin and lowers over the bottle and cap, allowing the forming wheels to rotate around the cap, forcing it to conform to the thread detail and tamper-proof shoulder on the bottles’ necks

Bottle Release: After a few rotations, the capping head automatically raises, and the operating buttons should be released. Once the ROPP Capping Head has stopped rotating, the ROPP capping process has been completed and the bottle can be removed from the machine ready for the next bottle.

Industries Using ROPP Capping Machines

ROPP capping machines find applications in various industries, including:

Pharmaceuticals: These machines are commonly used in pharmaceutical packaging to ensure the integrity and safety of medications, preventing tampering, and maintaining product freshness.

Beverages: ROPP capping machines are widely employed in the bottling of alcoholic beverages, such as wines, spirits, and liquors. The secure seal they provide helps preserve the flavour, aroma, and quality of the beverages.

Cosmetics: Many cosmetic products, such as perfumes, lotions, and oils, require reliable and aesthetically pleasing packaging. ROPP capping machines offer a premium seal while enhancing the overall packaging appeal.

Chemicals: Various chemical products, including household cleaners, solvents, and industrial chemicals, necessitate robust sealing to prevent leaks, spills, and contamination. ROPP capping machines ensure the safety and integrity of these products.

In summary, ROPP capping machines are essential equipment in the packaging industry, providing secure and tamper-evident sealing for bottles and containers. With their advantages in sealing efficiency, versatility, and ease of integration, these machines cater to diverse industries that prioritize product integrity, consumer.

Take a closer look at our ROPP Capping Machines