Liquid Filling Machines for Bottles, Jars & Containers – Built in the UK

Reliable Liquid Filling Machines for Every Industry

From small businesses to multinational brands, our machines provide precise, consistent results across industries.

Our liquid filling machines deliver precision and reliability for every production need. From semi-automatic liquid fillers for small batches to fully automatic liquid filling machines for high-volume lines, each bottle filling machine is built to handle liquids of all types — from free-flowing beverages and fragrances to viscous liquids, adhesives, and products with particulates.

Compact or large-scale, modular or fully custom, our filling equipment ensures consistent results, reduces downtime, and keeps your production line running efficiently.

Need help choosing the right liquid filling machine?

Our expert engineering team can guide you to the perfect solution. Contact us today to discuss your requirements and discover the ideal filling equipment for your business.

Precision Liquid Filling Machines – Designed & Manufactured in the UK

For 50 years, Universal Filling Machine Company has designed and manufactured high-precision liquid filling machines for businesses across the UK and worldwide. From compact semi-automatic fillers for small batch production to fully automatic liquid filling systems for high-speed lines, every machine is engineered in-house for reliability, accuracy, and long-term performance.

Our machines handle a wide range of products — from free-flowing beverages and fragrances to viscous liquids, adhesives, chemicals, and products containing particulates. Whether you require a standalone bottle filling machine or a fully integrated filling line, we build solutions tailored to your production needs.

Why Choose Universal Filling Machines?

- UK-based design & manufacture with 50+ years of experience

- Machines engineered for precision, speed, and reliability

- Full range: semi-automatic to fully automatic systems

- Handles liquids of all viscosities, particulates, and hazardous types

- Modular and custom-built options for any production scale

Need help choosing the right liquid filling machine?

Our expert engineering team can guide you to the perfect solution. Contact us today to discuss your requirements and discover the ideal filling equipment for your business.

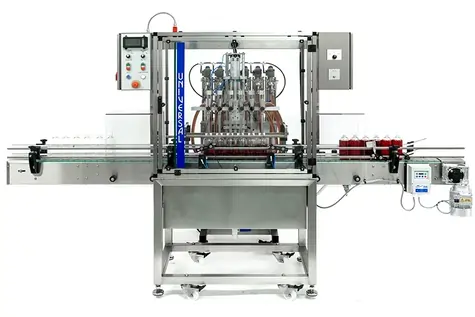

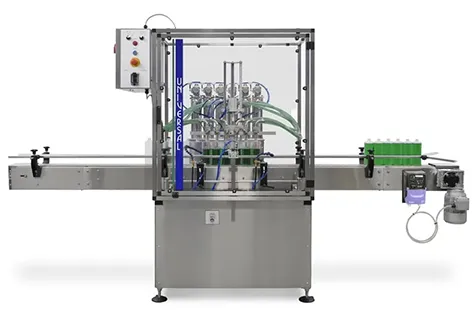

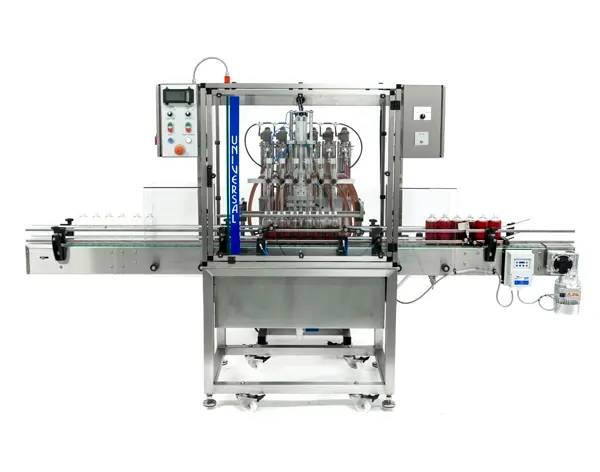

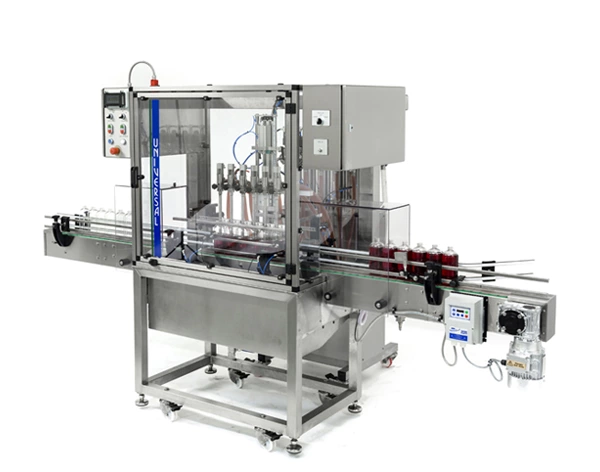

Automatic Liquid Filling Equipment – High-Speed Liquid Filling Machines

Our automatic liquid filling equipment is engineered for high-speed, high-volume bottle filling operations. These fully automated liquid filling machines feature advanced electro/pneumatic PLC controls for smooth operation and maximum efficiency on your production line.

Built to fill a variety of liquids — from free-flowing beverages to viscous syrups and products containing particulates — our machines handle container sizes from 5ml to 5 litres. Despite output speeds of up to 120 bottles per minute (7,200 per hour), our liquid filling machines are easy to set up, offer fast changeovers, and feature intuitive operation without specialist training.

Posimatic EV1000

The Posimatic EV1000 is a 2 to 12 Head Automatic Liquid Filling Machine / Bottle Filling Machine ideal for high-speed production lines.

Speed: Up to 120 bottles per minute

Filling Range: 5ml – 1,300ml

Perfect for beverages, viscous liquids, and products with particulates.

Posimatic EV2500

2, 4, 6 or 8 Head Automatic Liquid Filling Machine / Bottle Filling Machine for mid-volume production.

Speed: Up to 60 bottles per minute

Filling Range: 100ml – 2,500ml

Suitable for a range of liquids including thick syrups and adhesive-type products.

NEW Posimatic EVL

2 to 8 Head Automatic Liquid Filling Machine / Bottle Filling Machine designed for flexible production.

Speed: Up to 60 bottles/minute

Fill Range: 5ml – 5,000ml (model dependant)

Ideal for a wide variety of liquids, from thin beverages to thick sauces.

Posivac

2 to 12 Head Automatic Liquid Filling Machine using vacuum-level technology for precise filling.

Speed: Up to 80 bottles per minute

Filling Range: 2ml – 1,500ml

Perfect for thin liquids and small-volume products requiring high accuracy.

Automatic Liquid Filling Equipment – High-Speed Liquid Filling Machines

Our automatic liquid filling machines are designed for high-speed, high-volume bottle filling applications. These fully automated systems feature advanced electro/pneumatic PLC controls, ensuring smooth operation and maximum efficiency for your production line.

Built to fill a variety of liquids — including thick, viscous products and liquids containing particulates — our automatic filling equipment accommodates container sizes from 5ml to 5 litres. Despite reaching output speeds of up to 120 bottles per minute (7,200 per hour), our liquid filling machines are easy to set up, offer fast changeovers, and feature intuitive operation, eliminating the need for specialist training.

Semi-Automatic Liquid Filling Machines – Reliable Bottle Filling Equipment

Our semi-automatic liquid filling machines provide a cost-effective solution for small to medium-scale bottle filling operations. Most models operate using compressed air, simplifying installation and reducing maintenance, while handling a broad range of liquids — from free-flowing beverages and essential oils to thick syrups, adhesives, and particulate-rich products.

Posifill EF

Single Head Semi-Automatic Liquid Filling Machine / Bottle Filling Machine for small batch production.

Speed: 30 bottles per minute

Fill Range: 5–1,300ml

Fill from hopper or supply tank

Posifill EF2500

Single Head Semi-Automatic Liquid Filling Machine ideal for mid-size bottles and jars.

Speed: 30 bottles per minute

Fill Range: 200–2,500ml

Fill from hopper or supply tank

Posifill DP

Single Head Semi-Automatic Volumetric Liquid Filling Machine / Bottle Filling Machine for precise small batch filling.

Speed: 30 bottles per minute

Fill Range: 5–1,300ml

Fill from hopper or supply tank

Easifill

1 to 6 Head Semi-Automatic Vacuum Level Liquid Filling Machine suitable for thin liquids and low to medium volumes.

Speed: 40 bottles per minute

Fill Range: 10–500ml (typical)

Electric vacuum pump variant available

Posifill V-Twin/Four

2 or 4 Head Semi-Automatic Volumetric Liquid Filling Machine / Bottle Filling Machine for small batch production.

Speed: 40 bottles per minute

Fill Range: 5–1,300ml

PB5000

1 or 2 Head Semi-Automatic Volumetric Liquid Filling Machine suitable for large containers and chemical products.

Speed: 20 bottles per minute

Fill Range: 500ml – 10 litres

Glass & PVC option for bleach & acids

Compare Liquid Filling Machines

| Model | Fill Volume Range | Maximum Speed | Filling Heads | Valve Type | Container Types | Format |

|---|---|---|---|---|---|---|

| Posimatic EV1000 | 5ml – 1,300ml | Up to 120 containers/min | 2, 4, 6, 8 or 12 | Rotary Valve or Ball & Spring | Bottles, jars | Inline Automatic with Conveyor |

| Posimatic EV2500 | 100ml – 2,500ml | Up to 60 containers/min | 2, 4, 6 or 8 | Rotary Valve or Ball & Spring | Bottles, jars, tubs | Inline Automatic with Conveyor |

| Posimatic EV5000 | 250ml – 5,000ml | Up to 30 containers/min | 2, 4 or 6 | Rotary Valve or Ball & Spring | Jerrycans, tubs, bottles | Inline Automatic with Conveyor |

| Posimatic EVL | 5ml – 5,000ml (model dependent) | Up to 60 containers/min | 1, 2, 4, 6 or 8 | Rotary Valve or Ball & Spring | Bottles, jars, jerrycans, tubs, vials | Inline Automatic with Conveyor |

| Posivac | 2ml – 1,500ml | Up to 80 containers/min | 2 to 12 | N/A (vacuum filling) | Glass & rigid plastic bottles, jars | Inline Automatic with Conveyor |

| Posimatic Voluvac | 5ml – 5,000ml (typical) | Up to 120 containers/min | 2 to 12 | Rotary Valve & Vacuum Filling | Bottles, jars, jerrycans, tubs, pails | Inline Automatic with Conveyor |

| Posifill EF | 5ml – 1,300ml | Up to 30 containers/min | 1 | Rotary Valve or Ball & Spring | Bottles, jars | Benchtop |

| Posifill EF2500 | 200ml – 2,500ml | Up to 30 containers/min | 1 | Rotary Valve or Ball & Spring | Bottles, jars | Benchtop |

| Posifill DP | 5ml – 1,300ml | Up to 30 containers/min | 1 | Rotary Valve | Bottles, tubs, trays | Benchtop |

| Vacufill | 10ml – 500ml (typical) | Up to 40 containers/min | 1 or 2 | N/A (vacuum filling) | Glass & rigid plastic bottles, jars | Benchtop |

| Easifill | 10ml – 750ml (typical) | Up to 40 containers/min | 1, 2, 4 or 6 | N/A (vacuum filling) | Glass & rigid plastic bottles, jars | Free-standing |

| Posifill V-Twin/Four | 5ml – 1,300ml | Up to 40 containers/min | 2 or 4 | Rotary Valve or Ball & Spring | Bottles, jars | Free-standing |

| P5000 | 250ml – 5,000ml+ | Up to 15 containers/min | 1 or 2 | Rotary Valve | Jerrycans, tubs, bottles | Free-standing |

| PB5000 | 500ml – 5,000ml+ | Up to 20 containers/min | 1 or 2 | Rotary Valve | Bottles, cans, tubs, jerrycans | Free-standing |

| *Speeds are approximate and depend on fill volume, liquid characteristics, and operator efficiency. | ||||||

Frequently Asked Questions

What is a liquid filling machine?

A liquid filling machine dispenses measured volumes of liquid into bottles, jars or containers. They are used in industries such as food, chemical, cosmetics and pharmaceuticals to ensure accurate, consistent fills and reduce waste.

What types of liquid filling machines are available?

Universal Filling Machine Company manufactures semi-automatic and fully automatic liquid filling machines, including volumetric and vacuum-level systems. Each can be configured to suit a wide range of liquids and container types.

Which liquids can your machines fill?

Our machines handle thin and viscous products such as water, oils, detergents, sauces, chemicals, and cosmetics. Special options are available for corrosive or hazardous liquids.

Do you offer complete filling lines?

Yes. Universal designs complete turnkey lines including filling, capping, labelling and sealing equipment to meet your production needs.

What types of liquids can filling machines handle?

Different filling machines are suited to different types of liquids. For example, vacuum-level fillers work best with thin, free-flowing liquids where a consistent fill height is important, such as product on retail display, for example, but vacuum fillers rely on the container being able to withstand a vacuum without collapsing.

Volumetric fillers (sometimes referred to as piston fillers) are more versatile, capable of handling thicker liquids like sauces, gels, or creams, while still being accurate with low-viscosity products.

Choosing the right filling method ensures product quality and efficiency. Universal provides a wide range of technologies — vacuum, and volumetric fillers — to cover everything from corrosive chemicals to food-grade products.

Why invest in UK-built filling machines instead of cheaper imports?

While low-cost imported machines may seem attractive, they often fall short in reliability, hygiene standards, and compliance with UK and EU regulations. Many of these machines are not CE marked (some even have false CE markings), use inferior materials, and may even be unsafe to operate. In contrast, UK-built machines are engineered to meet stringent safety, hygiene, and performance standards.

Universal machines are built to last, with many still in daily use decades after installation. This makes them a far better long-term investment, saving money on downtime, repairs, and replacement equipment.

What’s the difference between semi-automatic and fully automatic filling machines?

Semi-automatic machines require an operator to present containers, press a foot pedal or button, and oversee the filling process. They are ideal for small to medium runs, flexible production, and businesses with frequent changeovers. Fully automatic systems integrate conveyors, sensors, and multiple fill heads to achieve much higher throughput with minimal operator intervention.

The right choice depends on your production scale and budget. Many businesses start with a semi-automatic machine, then upgrade to a fully automatic line as demand increases.

Universal’s semi-automatic filling machines can often be upgraded with additional features, smoothing the transition from semi- to fully-automatic filling.

How do I choose the right filling machine for my product?

Key factors include the viscosity of your liquid, the type of container, the required fill volume, and your production speed. For example, thin liquids in retail bottles may be best with a vacuum filler such as the Vacufill, Easifill or Posivac, while 5-litre containers of corrosive chemicals would require a volumetric filler specified to handle such liquids, such as our PB5000 or Posimatic EV5000.

Universal provides expert guidance and can recommend the right machine based on your specific product, often arranging trials to demonstrate the best solution.

Why Choose Universal Filling Machine Company?

50+ Years’ Experience as an Industry Leader

Built Using the Highest Quality Components and Materials

Machines Can Be Specified To Suit Almost Any Liquid

Outstanding Customer Service

Customers in Over 80 Countries Around the World

Designed and Manufactured in the UK

Quality & Service

Our customers range from small businesses to global brands, all relying on our liquid filling machines for accuracy and durability.

With over 45 years of experience in filling machinery, we’re proud that nearly 70% of our orders come from repeat customers who trust us for high-quality filling equipment and outstanding service. Every filling machine we produce undergoes rigorous in-house testing to ensure it meets our customers’ production goals and efficiency targets.

Find the Right Liquid Filling Machine for Your Business

At Universal, we know that every business has unique filling equipment requirements. That’s why we offer tailored filling machine solutions, designed to keep your production line efficient, scalable, and ready for future growth.

Our liquid filling machines are trusted across multiple industries, including Animal & Veterinary, Automotive, Chemicals, Cosmetics & Toiletries, Food & Drink, Home & Garden, and Pharmaceuticals.

We provide high-quality filling equipment designed for precision and efficiency, whether you need a bottle filling machine or a fully automatic liquid filling machine. Our advanced filling machinery streamlines production, handling a wide range of liquids with ease.

From small-scale operations to large manufacturing lines, our automatic filling machines deliver reliable performance and accuracy. Choose our liquid filling equipment to optimize your production process and meet industry standards.

Contact our team today to discuss your bottle filling machinery needs and find the perfect liquid filling machine to power your production success.

Case Studies

What type of filling machine are you looking for?

Juice Filling Machines

– High-precision machines for bottling juices, smoothies, and other beverages.

Drink Filling Machines

– Efficient beverage filling solutions for water, soft drinks, and mixed beverages.

Spirits Filling Machines

– Versatile solutions for bottling spirits, liqueurs, and alcoholic beverages efficiently.

Whisky Filling Machines

– Accurate spirit filling machines for whisky bottles, ideal for small and large distilleries.

Gin Filling Machines

– Semi-automatic and automatic machines for gin and other distilled spirits.

Liqueur Filling Machines

– Precise machines designed for filling high-value liqueurs with minimal spillage or waste.

Rum Filling Machines

– Tailored solutions for rum bottling, from batch production to high-speed lines.

Bottling Machines

– Complete solutions for high-volume liquid bottling, including filling, capping, and line integration.

Sauce Filling Machines

– Efficient machines for filling smooth and chunky sauces into jars and bottles, ideal for food production lines.

Ketchup Filling Machines

– Designed for thick sauces like ketchup and tomato puree, ensuring precise fill volumes.

Syrup Filling Machines

– Reliable filling systems for viscous syrups, sauces, and liquid concentrates.

Jam Filling Machines

– High-precision filling for jams, preserves, and thick fruit spreads.

Chemical Filling Machines

– Robust, corrosion-resistant equipment for filling flammable, acidic, or hazardous liquids safely.

Solvent Filling Machines

– Accurate and safe filling solutions for industrial chemicals and solvents.

Perfume Filling Machines

– Delicate and accurate filling machines for fragrance bottles and cosmetic liquids.

Shampoo Filling Machines

– Semi-automatic and automatic filling machines for viscous cosmetic liquids like shampoo and conditioner.

Bottle Filling Machines

– Flexible machines for filling a wide range of liquids into bottles, from cosmetics to food products.