A piston filler is a type of liquid filling machine that uses a piston and cylinder to fill containers with liquid products.

The piston is typically made of stainless steel or other durable material and is connected to a piston rod that is moved up and down by an air cylinder or motor.

During the filling process, the piston moves downwards, drawing liquid from a reservoir or hopper into the cylinder. As the piston reaches the bottom of the cylinder, a one-way valve opens, allowing the liquid to flow through the filling nozzle and into the container being filled. Once the container is filled to the desired level, the piston moves back up, and the valve closes, stopping the flow of liquid.

Piston fillers are ideal for filling high-viscosity products, such as creams, pastes, and gels, as well as liquids with particulates or solids. They are also versatile and can handle a wide range of container sizes and shapes, from small vials to large drums.

Piston fillers can be either manual or automatic, and can be designed to fill containers at various speeds and fill volumes. They are commonly used in industries such as food and beverage, cosmetics, pharmaceuticals, and chemical manufacturing, where accurate and consistent filling is important.

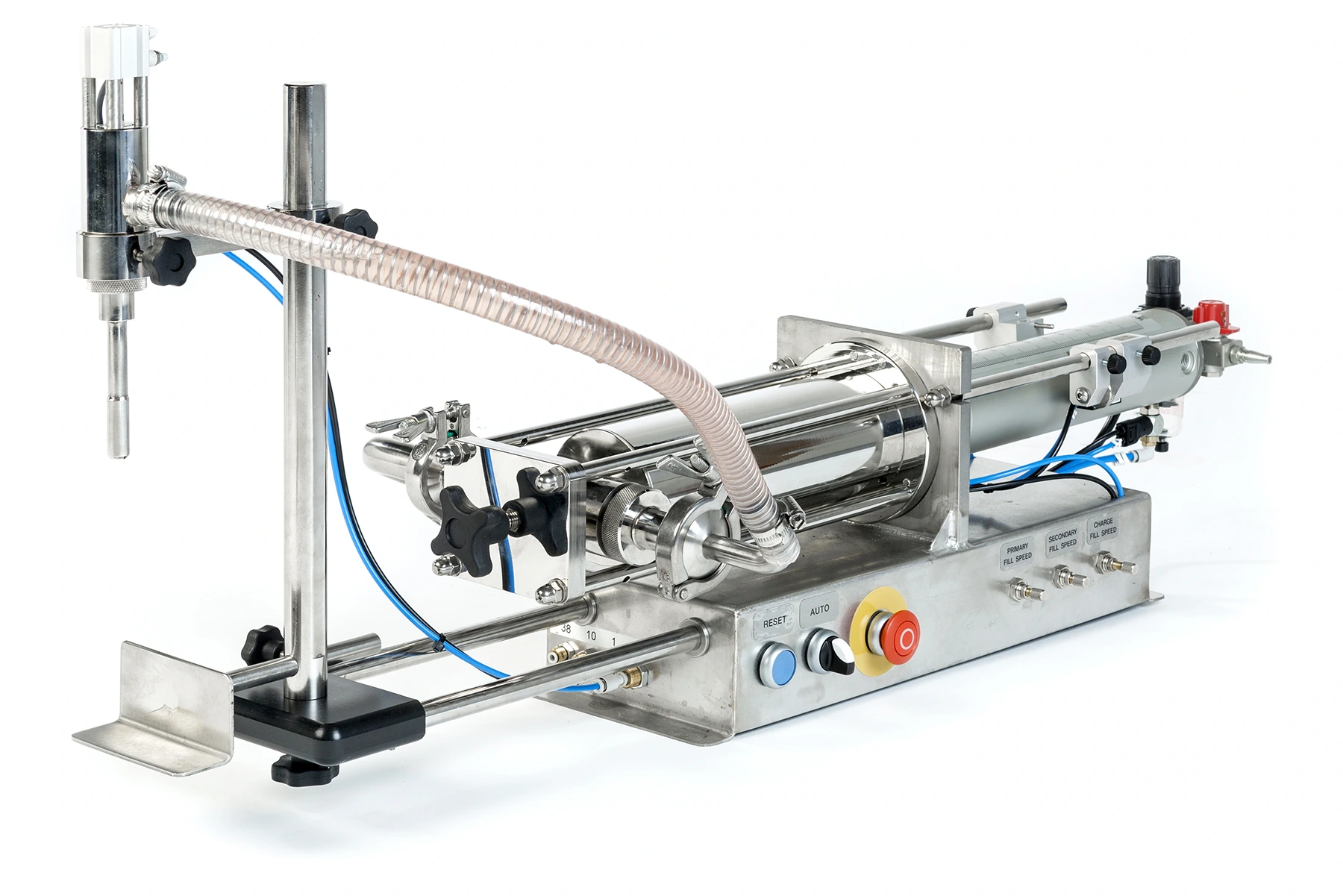

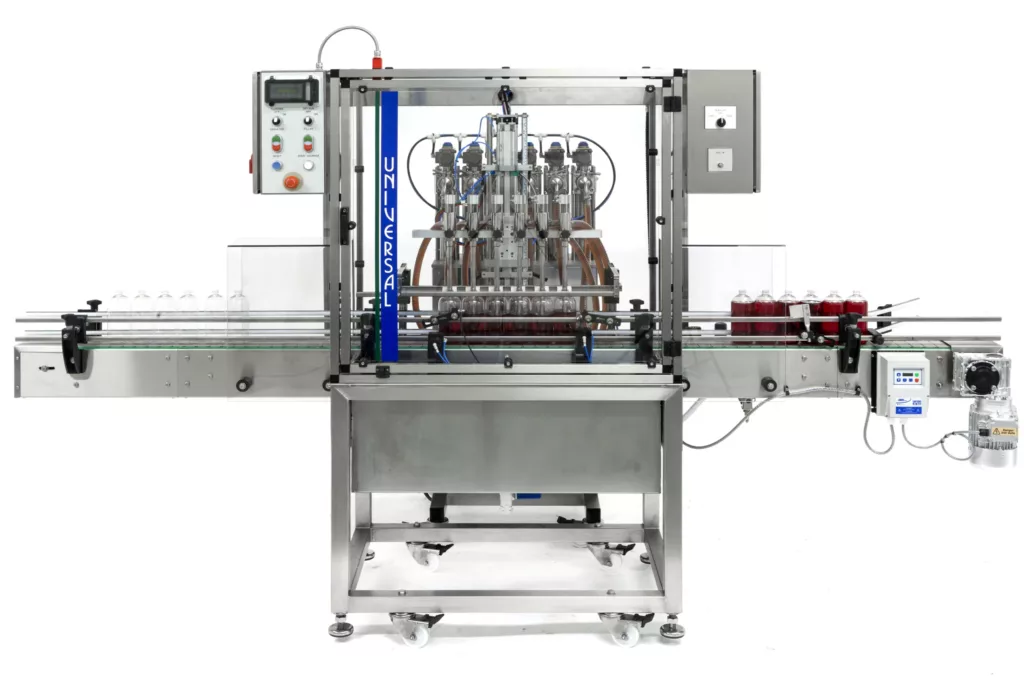

At Universal, manufacture a range of piston fillers, from tabletop semi-automatic machines such as our Posifill EF range, our freestanding semi-automatic machines such as our Posifill V-Twin/Four, P5000 and PB5000, to our fully automatic Posimatic EV1000, Posimatic EV2500 and Posimatic EV5000 inline filling machines.