A volumetric filler is a machine which fills containers with a predetermined quantity of liquid, measured by the volume displaced rather than, for example, weight or height within a bottle.

The volumetric filling machine working principle is a pneumatically-powered linear actuator connected to a piston within a cylinder. The piston is forced forwards and backwards for each filling cycle.

During this motion, a valve at the opposite end of the cylinder governs the flow of liquid; allowing it to exit the cylinder from the outfeed side as the piston moves forwards and allowing the cylinder to draw liquid from the infeed side as the piston moves backwards.

The length of the piston’s stroke can be adjusted to give the desired fill volume. The speed of the piston’s movement can also be controlled both fore and aft to ensure accurate filling volumes are achieved at acceptable speeds.

A filling nozzle is connected to the outfeed side of the metering cylinder’s valve, usually via a hose or pipe. This nozzle plays an important role in the filling process; it’s design, diameter and length should be specified to suit the liquid container and prevent dripping and any other undesired characteristics.

The infeed side of the metering cylinder’s valve is connected to either hopper or supply tank via a feed pipe, replenishing the cylinder as it moves backwards after each fill.

Universal Filling Machine Company manufacture several machines which use this filling principle and offer additional features such a secondary filling speed as an option. This allows for the latter part of the filling cycle to be completed at a reduced speed to avoid liquids splashing as a result of filling too fast. The speed and starting point of the secondary fill can both be set and have no effect on the overall filling volume.

Volumetric fillers can range from hand-operated, manual machines through to highly automated production lines and can fill volumes from 5ml to 5 litres in a single cycle. Multi-shot counters can also be used. These allow a number filling cycles to be completed in a single operation – a single press of the foot switch can be used to trigger 5×5 litre fills, giving a total of 25 litres in a single action.

The transparent metering cylinders fitted to this PB5000 enable you to see the liquid being displaced by the movement of the piston and actuator assembly.

As the piston rises, liquid is forced through the metering valve, to the filling nozzles. Once filling is complete, the metering valves switch to allow the piston to draw liquid in to the metering cylinder from the supply. The distance the the pistons travel can be adjusted to displace the correct volume of liquid.

The PB5000 volumetric filling machine is designed to handle acids, alkalines and bleaches. As a result, the contact parts are made from glass & PVC because even 316 stainless steel cannot withstand such liquids.

When filling is complete, the metering valve switches over, to only allow liquid to enter the metering from the intake hoses. Momentarily later, the actuator starts to draw the piston back, drawing fresh liquid in to the metering cylinders for the next cycle.

This particular model of liquid filling machine is a 2-head volumetric filler, which means it fills 2 containers at the same time. As the video shows, a single pneumatic actuator controls both pistons, to ensure fill volume consistency.

Universal’s range of Automatic and Semi-Automatic Volumetric Liquid Filling Machines

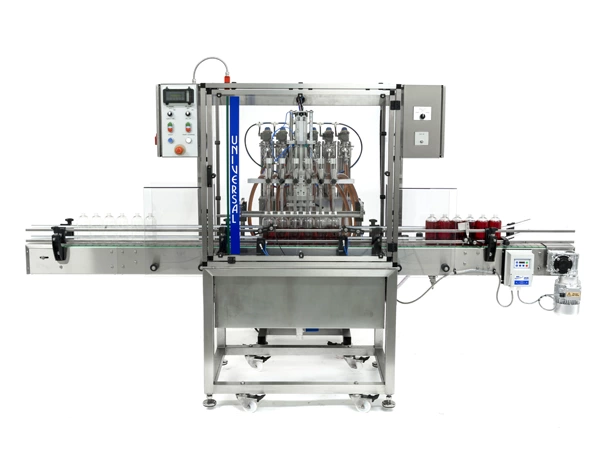

Posimatic EV1000

2, 4, 6, 8 or 12 Head Automatic Volumetric Filling Machine

Speed: 120 bottles per minute • Filling Range: 5ml – 1,300ml

Posimatic EV2500

2, 4, 6 or 8 Head Automatic Volumetric Filling Machine

Speed: 60 bottles per minute • Filling Range: 100ml – 2,500ml

Posifill V Twin/Four

2 or 4 Head Semi-Automatic

Volumetric Filling Machine

Speed: Up to 40 bottles/minute

Fill Range: 5–1,300ml

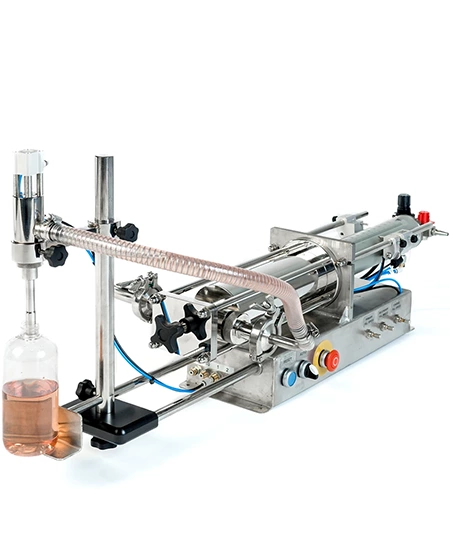

PB5000

1 or 2 Head Semi-Automatic

Volumetric Filling Machine

Glass & PVC option for bleach & acids

Speed: Up to 20 bottles/minute

Fill Range: 500ml – 10 litres

Posifill EF

Single Head Semi-Automatic Volumetric Filling Machine

Speed: Up to 30 bottles/min

Fill: 5–1,300ml/200–2,500ml

Fill from hopper or supply tank.

Posifill EF2500

Single Head Semi-Automatic Volumetric Filling Machine

Speed: Up to 30 bottles/min

Fill: 250–1,300ml/200–2,500ml

Fill from hopper or supply tank.