Can Universal’s filling machines fill carbonated drinks?

Carbonated liquids have substantially different characteristics to conventional liquids. They react to changes in pressure and agitation far more than liquids that are not carbonated.

The process of volumetric filling forces liquid into a container and the process of Vacuum Level filling draws liquid into a container by vacuum. Both processes will have an adverse effect on a carbonated liquid, causing it to fizz and overflow.

Most industrial-scale filling systems for carbonated drinks effectively produce a filling environment which is at a higher-than-atmospheric level of air pressure throughout the entire filling and capping cycle. The supply tank, filling system, and bottle are all pressurised with CO2 to an extent which forces some of the CO2 gas to be dissolved within the liquid while preventing it from fizzing and overflowing.

In such an environment, carbonated drinks behave much more like non-carbonated liquids and can be filled by gravity or volumetric filling.

Unfortunately, Universal Filling Machine Company don’t currently offer a system which maintains constant, balanced pressure throughout the filling cycle.

Can Universal’s filling machines fill carbonated drinks?

Carbonated liquids have substantially different characteristics to conventional liquids. They react to changes in pressure far more than liquids that are not carbonated.

The process of volumetric filling forces liquid into a container and the process of Vacuum Level filling draws liquid into a container by vacuum. Both processes will have an adverse effect on a carbonated liquid, causing it to fizz and overflow.

Most industrial-scale filling systems for carbonated drinks effectively produce a filling environment which is at a higher-than-atmospheric level of air pressure throughout the entire filling and capping cycle. The supply tank, filling system, and bottle are all pressurised with CO2 to an extent which forces some of the CO2 gas to be dissolved within the liquid while preventing it from fizzing and overflowing.

In such an environment, carbonated drinks behave much more like non-carbonated liquids and can be filled by gravity or volumetric filling.

Unfortunately, Universal Filling Machine Company don’t currently offer a system which maintains constant, balanced pressure throughout the filling cycle.

Universal are known for making machines that last. A combination of factors make this statement true, such as the quality of the materials and components we use, the expertise and attention to detail of our design and manufacturing teams, and our commitment to outstanding service.

This also means that when a customer contacts us regarding a particularly old machine, they are often pleasantly surprised to learn that we are more than willing and very able to help.

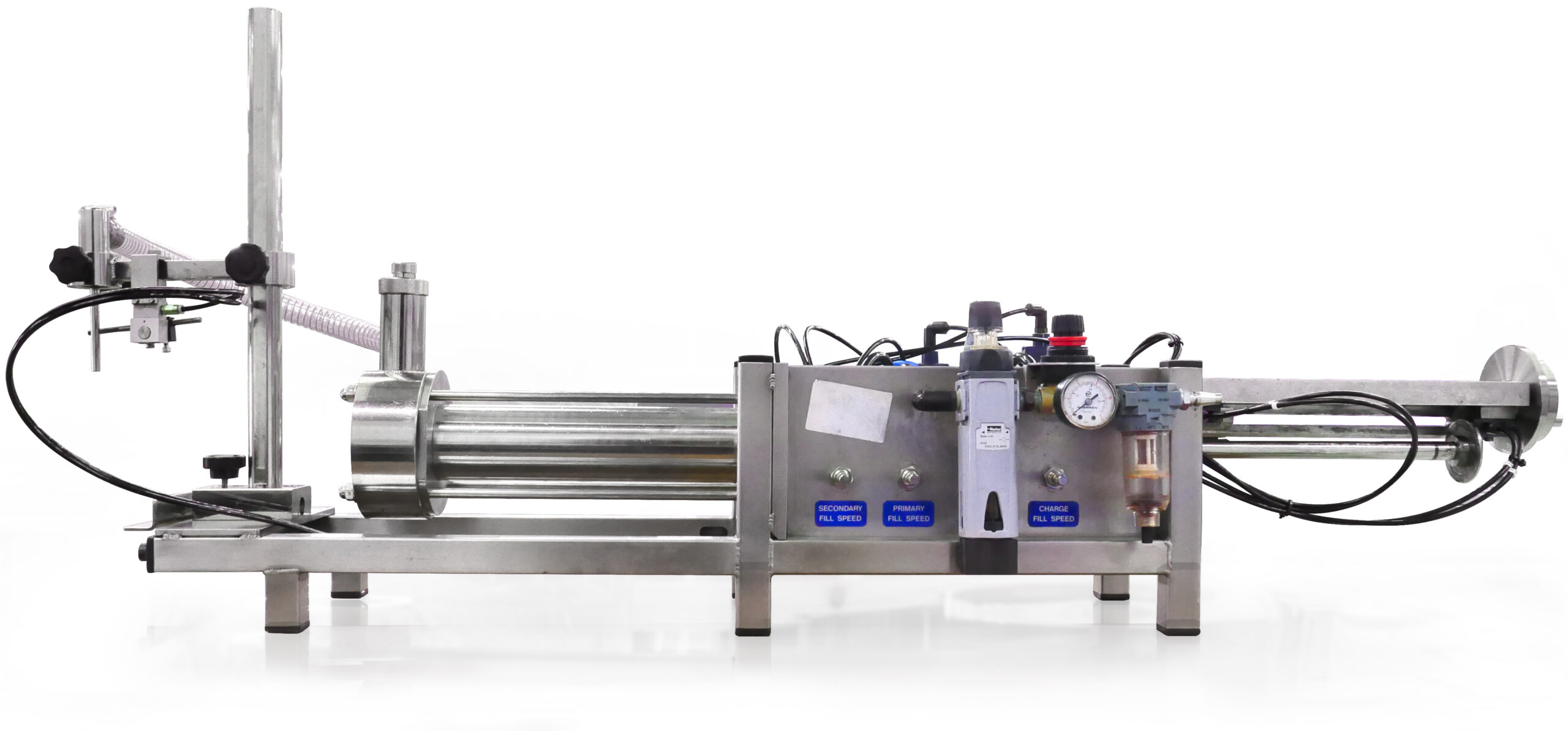

Such was the case with the machine shown here … a Posifill MkI. This machine, originally manufactured by us in 1984, was recently sent back to us for a service.

Still completely functional; just not performing as well as it could. All it needed after 38 years was a service by one of our skilled engineers to return it to perfect working order!

This isn’t an uncommon story; we regularly have machines returned for service dating from the 1980s which are still more than capable of doing their job.

We carry a huge range of spares for our entire product range, past and present, and it’s great to hear from delighted customers who are surprised to learn their machine has plenty of life left.

Do you have an older Universal Filling Machine?

Contact us to arrange a service: +44 (0)1233 643666, or email salesuk@universalfilling.com

The latest version of this machine; the Posifill EF is built to the same uncompromising standard as the original, using 316 stainless steel contact parts throughout and shares many components with our fully automatic filling systems.